Rare earth elements (REEs) play a pivotal role in the advancement of modern technology, serving as essential components in a wide array of devices and systems. These elements, which include lanthanides and some actinides, are critical for the production of high-performance magnets, phosphors, catalysts, and batteries. Their unique properties enable the development of cutting-edge technologies, from smartphones and electric vehicles to wind turbines and advanced military equipment.

As the world becomes increasingly reliant on technology, the demand for REEs continues to surge, underscoring their importance in driving innovation and economic growth. The significance of rare earth elements extends beyond mere technological applications; they are also integral to national security and energy independence. Countries that possess substantial reserves of these elements can leverage them to enhance their technological capabilities and reduce reliance on foreign imports.

This strategic advantage has led to heightened interest in REEs, prompting nations to invest in research and development to secure their supply chains. As industries evolve and new technologies emerge, the role of rare earth elements will only become more pronounced, making them a cornerstone of future advancements.

Key Takeaways

- Rare earth elements are crucial for the production of technology, including renewable energy and electronics.

- Rare earth elements were first discovered in the late 18th and early 19th centuries, and their unique properties have made them essential for modern technology.

- Rare earth elements play a vital role in the development and production of renewable energy sources such as wind turbines and electric vehicles.

- The mining of rare earth elements can have significant environmental impacts, including habitat destruction and water pollution.

- Rare earth elements are used in a wide range of electronic devices, from smartphones and computers to advanced medical equipment.

The History and Discovery of Rare Earth Elements

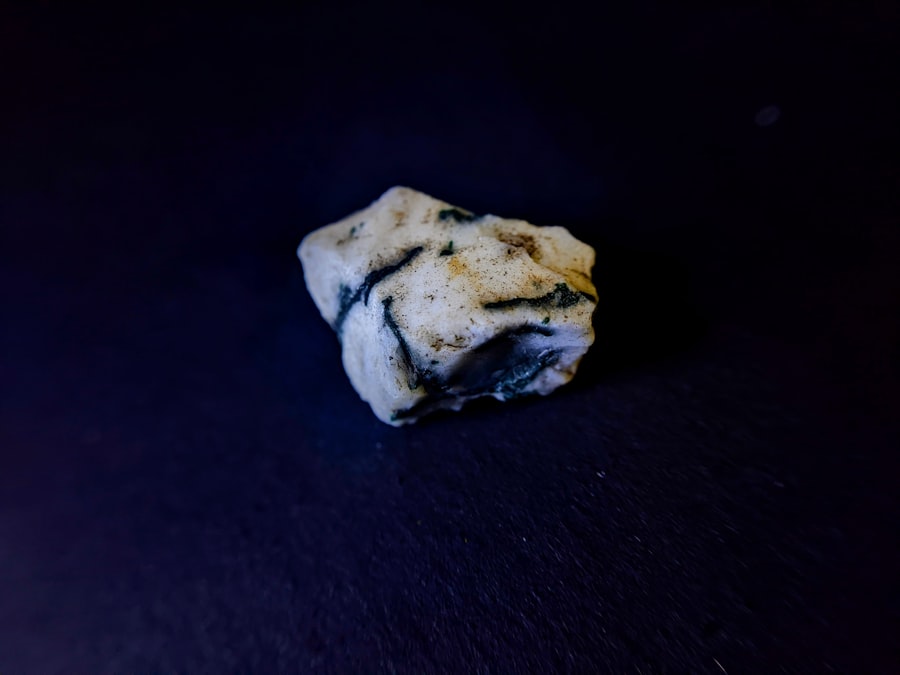

The journey of rare earth elements began in the late 18th century when Swedish chemist Johan Gadolin first isolated a new mineral called yttria from a sample of gadolinite.

Over the following decades, scientists such as Martin Heinrich Klaproth and Pierre and Marie Curie contributed to the understanding of these elements, isolating and naming many of them.

The term “rare earth” was coined in the 19th century, reflecting the initial perception that these elements were scarce and difficult to extract. As the 20th century progressed, the importance of rare earth elements became increasingly evident, particularly during World War II when they were utilized in various military applications. The post-war era saw a surge in demand for REEs as industries began to recognize their potential in electronics, optics, and materials science.

The establishment of large-scale mining operations in countries like China, the United States, and Australia further facilitated the extraction and commercialization of these elements. This historical context highlights not only the scientific achievements associated with rare earth elements but also their growing significance in global markets.

The Role of Rare Earth Elements in Renewable Energy

Renewable energy technologies heavily rely on rare earth elements to enhance efficiency and performance. For instance, wind turbines utilize powerful neodymium-iron-boron magnets, which are essential for converting wind energy into electricity. These magnets are not only lightweight but also capable of generating strong magnetic fields, making them ideal for modern turbine designs.

Similarly, rare earth elements are crucial in the production of batteries for electric vehicles (EVs), where they contribute to improved energy density and longevity. As the world shifts towards sustainable energy solutions, the demand for REEs in this sector is expected to grow exponentially. Moreover, rare earth elements play a vital role in energy storage technologies, such as lithium-ion batteries and solid-state batteries.

These advancements are critical for addressing the intermittent nature of renewable energy sources like solar and wind power. By enhancing battery performance, REEs help facilitate the transition to a more sustainable energy grid. As governments and industries worldwide commit to reducing carbon emissions and investing in renewable energy infrastructure, the importance of rare earth elements in achieving these goals cannot be overstated.

The Environmental Impact of Rare Earth Element Mining

| Environmental Impact | Rare Earth Element Mining |

|---|---|

| Water Pollution | High levels of toxic substances released into water sources |

| Air Pollution | Release of dust and other harmful particles into the air |

| Deforestation | Clearing of land for mining activities |

| Habitat Destruction | Disruption of ecosystems and wildlife habitats |

| Radioactive Waste | Generation of radioactive waste during processing |

While rare earth elements are indispensable for modern technology and renewable energy solutions, their extraction poses significant environmental challenges. Mining operations often result in habitat destruction, soil degradation, and water pollution due to the toxic byproducts generated during processing. The extraction process typically involves open-pit mining or underground mining techniques that can disrupt local ecosystems and lead to long-term environmental damage.

Additionally, the chemicals used in refining REEs can contaminate water sources, posing risks to both human health and wildlife. Efforts to mitigate these environmental impacts have gained traction in recent years, with some companies adopting more sustainable mining practices. Innovations such as bioremediation and closed-loop systems aim to reduce waste and minimize ecological footprints.

However, these practices are not yet widespread, and many mining operations continue to prioritize profit over environmental stewardship. As awareness of these issues grows, there is an increasing call for stricter regulations and more responsible sourcing practices within the rare earth element industry.

The Use of Rare Earth Elements in Electronics

The electronics industry is one of the largest consumers of rare earth elements, utilizing them in various applications that enhance device performance and functionality. For example, REEs are integral to the production of high-quality displays found in smartphones, televisions, and computer monitors. Phosphors containing europium and terbium are used to create vibrant colors in LED screens, while neodymium is essential for miniaturized speakers that deliver superior sound quality.

These applications highlight how rare earth elements contribute to the consumer electronics that have become ubiquitous in daily life. Furthermore, rare earth elements are crucial for advancements in telecommunications technology. They are used in fiber optic cables and signal amplifiers that enable high-speed internet connectivity.

As global demand for faster and more reliable communication networks continues to rise, the role of REEs in supporting these technologies becomes increasingly vital. The integration of rare earth elements into electronics not only enhances user experience but also drives innovation across various sectors, reinforcing their significance in contemporary society.

The Global Demand for Rare Earth Elements

The global demand for rare earth elements has surged dramatically over the past few decades, driven by technological advancements and a growing emphasis on renewable energy solutions. As countries strive to transition away from fossil fuels and invest in clean energy infrastructure, the need for REEs has become more pronounced. Industries such as electric vehicles, renewable energy generation, and advanced electronics are at the forefront of this demand surge, creating a competitive landscape for sourcing these critical materials.

China currently dominates the global supply chain for rare earth elements, accounting for a significant portion of production and processing capabilities. This concentration has raised concerns among other nations regarding supply security and geopolitical implications. As countries seek to diversify their sources of REEs, investments in domestic mining operations and recycling initiatives have gained momentum.

The increasing global demand for rare earth elements underscores their importance not only for technological progress but also for economic stability and national security.

The Geopolitical Implications of Rare Earth Element Production

The geopolitical landscape surrounding rare earth element production is complex and multifaceted. With China holding a dominant position in the global supply chain, other nations have become increasingly aware of their vulnerability regarding access to these critical materials. This has led to strategic initiatives aimed at securing alternative sources of REEs through partnerships with countries rich in mineral resources or by investing in domestic mining projects.

The competition for control over rare earth element supplies has implications for international relations, trade policies, and national security strategies. Moreover, tensions between major powers can exacerbate concerns over rare earth element availability. For instance, trade disputes between China and the United States have highlighted the potential risks associated with reliance on a single supplier for critical materials.

As nations recognize the strategic importance of REEs, there is a growing push for collaboration on research and development efforts aimed at finding substitutes or improving recycling technologies. The geopolitical implications of rare earth element production underscore the need for countries to adopt proactive measures to ensure a stable supply chain while fostering international cooperation.

The Challenges of Sourcing and Supplying Rare Earth Elements

Sourcing and supplying rare earth elements present numerous challenges that impact both industry stakeholders and policymakers. One significant hurdle is the environmental impact associated with mining operations, which can deter investment and lead to public opposition against new projects. Additionally, regulatory frameworks governing mining practices vary widely across countries, complicating efforts to establish consistent standards for responsible sourcing.

Another challenge lies in the complex processing required to extract pure rare earth elements from ores. This process often involves multiple stages that can be costly and time-consuming. Furthermore, fluctuations in global demand can create instability within supply chains, leading to price volatility that affects manufacturers reliant on these materials.

Addressing these challenges requires collaboration among governments, industry leaders, and researchers to develop innovative solutions that promote sustainable practices while ensuring a reliable supply of rare earth elements.

The Future of Rare Earth Element Technology

The future of rare earth element technology is poised for significant transformation as industries adapt to evolving demands and environmental considerations. Innovations in material science may lead to the development of alternative materials that can replace or reduce reliance on traditional REEs without compromising performance. Research into synthetic substitutes or enhanced recycling methods could reshape how these critical materials are sourced and utilized.

Moreover, advancements in extraction techniques may improve efficiency while minimizing environmental impacts associated with mining operations. Technologies such as hydrometallurgy or bioleaching hold promise for more sustainable extraction processes that could revolutionize the industry. As awareness grows regarding the importance of responsible sourcing practices, stakeholders will likely prioritize sustainability alongside technological advancement in shaping the future landscape of rare earth element technology.

The Potential for Recycling Rare Earth Elements

Recycling rare earth elements presents a viable solution to address supply chain challenges while mitigating environmental impacts associated with mining operations. As electronic waste continues to accumulate globally, there is an increasing recognition of the value contained within discarded devices that often contain significant amounts of REEs. By developing efficient recycling processes capable of recovering these materials from end-of-life products, industries can reduce dependence on virgin resources while promoting circular economy principles.

Several initiatives have emerged aimed at enhancing recycling capabilities for rare earth elements.

As technology evolves and public awareness increases regarding e-waste management’s importance, recycling rare earth elements could become an integral part of sustainable resource management strategies.

The Ethical Considerations of Rare Earth Element Mining and Production

The ethical considerations surrounding rare earth element mining and production are complex and multifaceted. Concerns about labor practices within mining operations often arise, particularly in regions where regulations may be lax or enforcement weak. Reports of unsafe working conditions or exploitation highlight the need for greater transparency within supply chains to ensure ethical sourcing practices are upheld.

Additionally, communities located near mining sites may face adverse effects from environmental degradation caused by extraction activities. Addressing these ethical dilemmas requires collaboration among stakeholders—including governments, industry leaders, non-governmental organizations (NGOs), and local communities—to establish standards that prioritize human rights alongside environmental sustainability. By fostering dialogue around ethical considerations within the rare earth element industry, stakeholders can work towards creating a more responsible framework that balances economic interests with social responsibility.

In conclusion, rare earth elements are indispensable components driving technological innovation across various sectors while posing significant environmental challenges associated with their extraction. As global demand continues to rise amid geopolitical tensions surrounding supply chains, addressing sourcing challenges through sustainable practices becomes paramount for ensuring long-term availability without compromising ethical standards or environmental integrity.

Rare earth elements play a crucial role in the advancement of modern technology, serving as essential components in everything from smartphones to electric vehicles. These elements, often found in small quantities, are vital for the production of high-performance magnets, batteries, and other electronic components. The demand for rare earth elements has surged in recent years, driven by the rapid growth of the tech industry and the push towards renewable energy solutions. For a deeper understanding of the significance of rare earth elements in technology and their impact on global supply chains, you can explore a related article on this topic by visiting this page.

WATCH THIS! They Can Shut Down Your World Overnight. This Is The Choke Point Controlling Everything!

FAQs

What are rare earth elements?

Rare earth elements are a group of 17 chemical elements in the periodic table, including scandium, yttrium, and the 15 lanthanides. They are essential for the production of various high-tech products and are known for their unique magnetic, luminescent, and catalytic properties.

How are rare earth elements used in technology?

Rare earth elements are used in a wide range of technologies, including smartphones, electric vehicles, wind turbines, and medical devices. They are crucial for the production of magnets, batteries, catalysts, and phosphors in these devices.

Why are rare earth elements important in technology?

Rare earth elements are important in technology because of their unique properties that make them essential for the production of high-performance and energy-efficient devices. They play a critical role in advancing various technological innovations.

Where are rare earth elements found?

Rare earth elements are found in various parts of the world, with significant deposits in China, Australia, the United States, and several other countries. They are typically extracted from rare earth minerals and ores through a complex process.

Are rare earth elements truly rare?

Despite their name, rare earth elements are not actually rare in terms of abundance in the Earth’s crust. However, they are often found in low concentrations and are challenging to extract, making their production more complex and costly compared to other elements.