Rare earth magnets, known for their exceptional strength and versatility, have become indispensable in various modern applications. These magnets are primarily composed of rare earth elements, which are a group of 17 chemically similar elements found in the periodic table. The most commonly used rare earth magnets are neodymium-iron-boron (NdFeB) magnets, which are renowned for their remarkable magnetic properties.

Their ability to produce strong magnetic fields in compact sizes has revolutionized industries ranging from electronics to renewable energy. As technology continues to advance, the demand for these powerful magnets is expected to grow, highlighting their significance in contemporary society. The unique characteristics of rare earth magnets stem from the intrinsic properties of the rare earth elements themselves.

These elements exhibit high magnetic susceptibility and can maintain their magnetism even at elevated temperatures. This makes them particularly valuable in applications where space is limited and efficiency is paramount. From electric vehicles to wind turbines, rare earth magnets play a crucial role in enhancing performance and energy efficiency, making them a focal point of research and development in various fields.

Key Takeaways

- Rare earth magnets are powerful magnets made from rare earth elements, which are a group of 17 chemical elements in the periodic table.

- Rare earth elements were first discovered in the late 18th and early 19th centuries, but it wasn’t until the 1960s that they were used to create powerful magnets.

- The extraction and refinement process of rare earth elements involves several steps, including mining, crushing, and chemical processing.

- Rare earth elements play a crucial role in the production of magnets due to their unique magnetic properties, such as high coercivity and energy product.

- Rare earth magnet alloys are created by combining rare earth elements with transition metals to enhance their magnetic properties.

The Discovery of Rare Earth Elements

The journey of rare earth elements began in the late 18th century when Swedish chemist Johan Gadolin first isolated a new mineral called gadolinite. This marked the beginning of a long exploration into the unique properties of these elements. Over the following decades, scientists such as Martin Heinrich Klaproth and Charles-Gustave de Morveau contributed to the identification and classification of these elements, leading to the eventual recognition of the lanthanide series.

The discovery of these elements was not merely an academic pursuit; it laid the groundwork for future technological advancements that would rely on their unique properties. As research progressed, the understanding of rare earth elements expanded significantly. By the mid-20th century, scientists had successfully isolated several of these elements, including neodymium and dysprosium, which would later become critical in the production of high-performance magnets.

The Cold War era further accelerated interest in rare earth elements due to their strategic importance in military applications. This period saw increased investment in mining and refining technologies, setting the stage for the widespread use of rare earth elements in various industries.

The Extraction and Refinement Process

The extraction of rare earth elements is a complex and often environmentally challenging process. These elements are typically found in low concentrations within ores, necessitating extensive mining operations. The most common sources of rare earth elements include bastnäsite and monazite, which are mined primarily in China, Australia, and the United States.

Once extracted, the ores undergo a series of processes to separate the rare earth elements from other minerals and impurities. Refinement involves several stages, including crushing, grinding, and chemical processing. The crushed ore is treated with acids or alkalis to dissolve the rare earth elements, which are then precipitated out through various chemical reactions.

This process can generate significant waste and environmental concerns, prompting ongoing research into more sustainable extraction methods. Innovations such as bioleaching and solvent extraction are being explored to minimize environmental impact while maximizing yield.

The Role of Rare Earth Elements in Magnet Production

| Rare Earth Element | Percentage in Magnet | Application |

|---|---|---|

| Neodymium | 31% | Electric vehicle motors, wind turbines |

| Praseodymium | 30% | High-strength permanent magnets |

| Dysprosium | 3% | High-temperature applications |

| Terbium | 1% | Green energy technologies |

Rare earth elements are integral to the production of high-performance magnets due to their unique magnetic properties. Neodymium, for instance, is a key component in neodymium magnets, providing exceptional magnetic strength that surpasses traditional magnet materials like ferrite or alnico. The presence of other rare earth elements, such as praseodymium and dysprosium, can enhance specific properties, such as temperature stability and coercivity, making them suitable for demanding applications.

The combination of these elements allows manufacturers to create magnets that are not only powerful but also lightweight and compact. This is particularly advantageous in industries where space and weight constraints are critical factors, such as aerospace and automotive engineering. As technology evolves, the demand for more efficient and powerful magnets continues to rise, further solidifying the role of rare earth elements in magnet production.

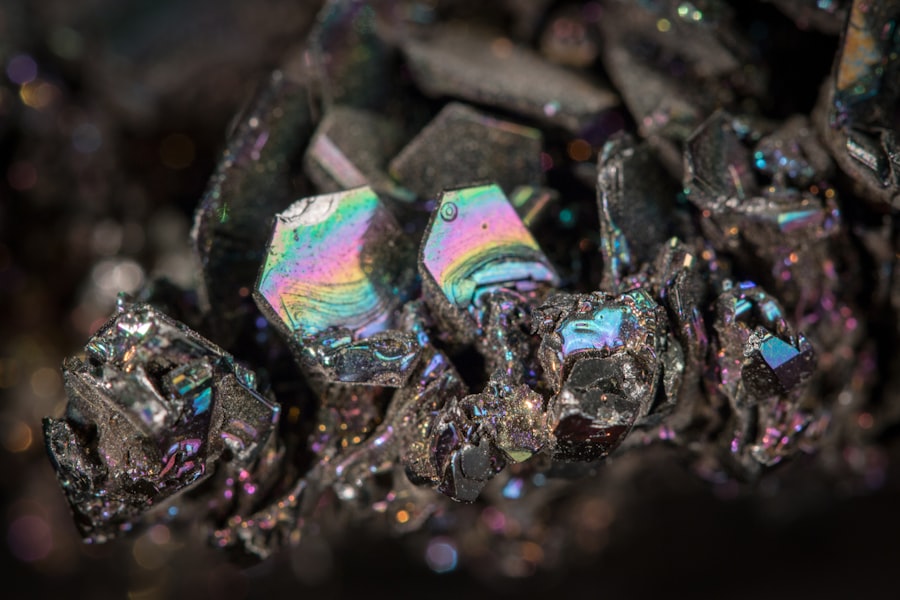

The Creation of Rare Earth Magnet Alloys

The production of rare earth magnet alloys involves a meticulous process that combines various metals with rare earth elements to achieve desired magnetic properties. Typically, neodymium is alloyed with iron and boron to create NdFeB magnets, which are known for their high energy density. The precise ratios of these components can significantly influence the final product’s performance characteristics, including its magnetic strength and resistance to demagnetization.

In addition to neodymium-iron-boron alloys, other combinations may include elements like dysprosium or terbium to enhance thermal stability or coercivity. The alloying process requires careful control over temperature and composition to ensure uniformity and optimal performance. As manufacturers continue to innovate, new alloy formulations are being developed to meet the evolving demands of various applications, from consumer electronics to renewable energy systems.

The Importance of Rare Earth Magnets in Modern Technology

Rare earth magnets have become a cornerstone of modern technology, playing a vital role in numerous applications that shape everyday life. In consumer electronics, these magnets are found in smartphones, laptops, and headphones, where they enable compact designs without sacrificing performance.

Beyond consumer electronics, rare earth magnets are essential in renewable energy technologies. Wind turbines utilize these magnets in their generators to convert kinetic energy into electrical energy efficiently. Similarly, electric vehicles rely on rare earth magnets for their motors, enhancing performance while reducing weight and energy consumption.

As society increasingly shifts towards sustainable energy solutions, the importance of rare earth magnets will only continue to grow.

The Manufacturing Process of Rare Earth Magnets

The manufacturing process of rare earth magnets is a sophisticated operation that requires precision and expertise. It typically begins with the production of alloy powders through techniques such as melt-spinning or hydrogen decrepitation. These powders are then subjected to a process called sintering, where they are compacted under high pressure and heated to form solid magnets.

After sintering, the magnets undergo machining to achieve specific shapes and sizes required for various applications. This step often involves grinding or cutting the magnets with diamond-coated tools due to their hardness. Finally, surface treatments may be applied to enhance corrosion resistance and durability.

The entire manufacturing process demands strict adherence to quality standards to ensure that the final product meets performance specifications.

Quality Control and Testing of Rare Earth Magnets

Quality control is paramount in the production of rare earth magnets, as even minor deviations can significantly impact performance. Manufacturers implement rigorous testing protocols throughout the production process to ensure that each batch meets established standards. This includes measuring magnetic properties such as remanence, coercivity, and energy product using specialized equipment.

In addition to magnetic testing, physical inspections are conducted to assess dimensions and surface quality. Advanced techniques such as X-ray diffraction may be employed to analyze the microstructure of the magnets, ensuring consistency and reliability. By maintaining stringent quality control measures, manufacturers can deliver high-performance rare earth magnets that meet the demands of various industries.

Environmental and Sustainability Considerations

The extraction and production of rare earth magnets raise important environmental concerns that cannot be overlooked. Mining operations can lead to habitat destruction, soil erosion, and water contamination if not managed responsibly. Additionally, the chemical processes involved in refining rare earth elements can generate hazardous waste that poses risks to both human health and ecosystems.

In response to these challenges, there is a growing emphasis on sustainability within the industry. Efforts are being made to develop more environmentally friendly extraction methods and recycling programs for rare earth materials. By reclaiming rare earth elements from end-of-life products such as electronics or batteries, manufacturers can reduce reliance on virgin materials while minimizing environmental impact.

The Future of Rare Earth Magnet Production

The future of rare earth magnet production appears promising yet complex as global demand continues to rise alongside technological advancements. Researchers are actively exploring alternative materials that could potentially reduce dependence on traditional rare earth elements while maintaining desirable magnetic properties. Innovations in material science may lead to breakthroughs that could reshape the landscape of magnet production.

Moreover, geopolitical factors play a significant role in shaping the future of rare earth magnet supply chains. As countries seek to secure access to these critical materials amid rising tensions and trade disputes, investments in domestic mining and refining capabilities are likely to increase.

The Impact of Rare Earth Magnets on Society

Rare earth magnets have undeniably transformed modern society by enabling advancements across various sectors. Their unique properties have facilitated innovations in technology that enhance everyday life while contributing significantly to sustainable energy solutions. As industries continue to evolve and adapt to new challenges, the importance of rare earth magnets will only grow.

However, it is crucial for stakeholders within this industry—ranging from manufacturers to policymakers—to prioritize sustainable practices that mitigate environmental impacts associated with extraction and production processes. By fostering responsible sourcing and recycling initiatives, society can harness the benefits of rare earth magnets while safeguarding the planet for future generations. Ultimately, the impact of rare earth magnets extends far beyond their physical properties; they represent a critical intersection between technology and sustainability in an ever-changing world.

Rare earth magnets, known for their exceptional strength and versatility, are a crucial component in various modern technologies, from electric vehicles to wind turbines. The process of making these powerful magnets involves several intricate steps, including mining, refining, and alloying rare earth elements like neodymium and samarium. For a deeper understanding of the complexities involved in the production of rare earth magnets, you can explore a related article on this topic by visiting this page. This article delves into the detailed processes and technological advancements that have made the production of rare earth magnets more efficient and sustainable.

WATCH THIS! They Can Shut Down Your World Overnight. This Is The Choke Point Controlling Everything!

FAQs

What are rare earth magnets?

Rare earth magnets are a type of permanent magnet made from the rare earth elements neodymium and samarium. They are known for their strong magnetic properties and are used in a wide range of applications, including electronics, automotive components, and industrial machinery.

How are rare earth magnets made?

Rare earth magnets are made through a process called sintering, which involves compacting and heating a mixture of rare earth metals and other elements to form a solid material. The resulting material is then shaped into the desired magnet shape and magnetized to create a strong magnetic field.

What are the steps involved in making rare earth magnets?

The steps involved in making rare earth magnets include:

1. Mining and extraction of rare earth elements

2. Purification and processing of the rare earth elements

3. Mixing the rare earth elements with other metals to form a magnet alloy

4. Compact the alloy into the desired shape

5. Sintering the compacted alloy at high temperatures

6. Machining and finishing the sintered magnet

7. Magnetizing the finished magnet to create a strong magnetic field

What are the applications of rare earth magnets?

Rare earth magnets are used in a wide range of applications, including:

– Electric motors and generators

– Magnetic resonance imaging (MRI) machines

– Magnetic separators

– Magnetic bearings

– Loudspeakers and headphones

– Magnetic couplings

– Wind turbine generators

– Hard disk drives