The electric vehicle (EV) industry has witnessed a remarkable transformation over the past decade, driven by technological advancements and a growing awareness of environmental sustainability. At the heart of this revolution lies the electric motor, which relies heavily on high-performance magnets to function efficiently. The supply chain for these magnets is complex and multifaceted, involving various materials, manufacturing processes, and geopolitical considerations.

Understanding this supply chain is crucial for stakeholders in the automotive industry, as it directly impacts the production and performance of electric vehicles. The magnet supply chain for EV motors is not merely a logistical network; it is a critical component that influences the overall viability of electric vehicles. As demand for EVs continues to surge, the need for reliable and sustainable sources of magnets becomes increasingly pressing.

This article delves into the intricacies of the EV motor magnet supply chain, exploring the factors driving demand, the importance of magnets in motor performance, and the challenges faced in sourcing essential materials.

Key Takeaways

- The demand for electric vehicles is increasing, leading to a growing need for magnets in EV motors.

- Magnets play a crucial role in the performance and efficiency of EV motors, making their supply chain essential to the electric vehicle industry.

- Sourcing rare earth materials for magnets presents challenges due to geopolitical issues and supply chain disruptions.

- The production of magnets has environmental impacts that need to be addressed for sustainable electric vehicle manufacturing.

- Diversifying magnet suppliers and considering regulatory and policy considerations are important strategies for ensuring a stable EV motor magnet supply chain in the future.

Increasing Demand for Electric Vehicles

The global shift towards electric mobility has been fueled by a combination of regulatory pressures, technological advancements, and changing consumer preferences. Governments around the world are implementing stringent emissions regulations and offering incentives to promote the adoption of electric vehicles. This has led to a significant increase in EV sales, with projections indicating that electric vehicles could account for a substantial portion of new car sales in the coming years.

As more consumers opt for electric vehicles, automakers are ramping up production to meet this burgeoning demand. This surge in production not only necessitates a steady supply of components but also places immense pressure on the supply chains that support these components. Among these components, magnets play a pivotal role in ensuring that electric motors operate efficiently and effectively.

The increasing demand for EVs thus directly correlates with a heightened need for high-quality magnets, making it imperative for manufacturers to secure reliable sources.

Importance of Magnets in EV Motors

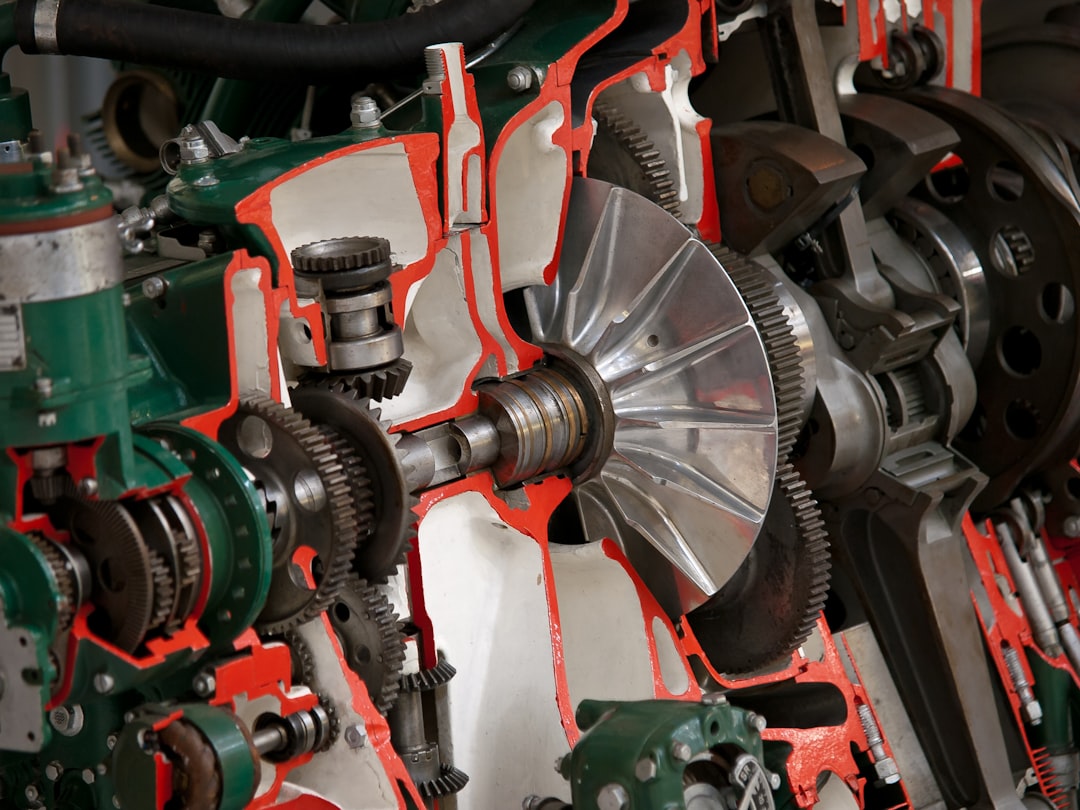

Magnets are integral to the operation of electric motors, serving as the driving force behind their functionality. In EVs, permanent magnets are commonly used in synchronous motors, which are known for their efficiency and performance. These magnets enable the conversion of electrical energy into mechanical energy, allowing vehicles to accelerate smoothly and maintain speed with minimal energy loss.

The quality and composition of these magnets can significantly influence the overall performance of an electric vehicle. Moreover, the use of high-performance magnets can enhance the range and efficiency of electric vehicles. As automakers strive to improve battery life and reduce charging times, the role of magnets becomes even more critical.

Advanced magnet technologies can lead to lighter and more compact motor designs, which contribute to overall vehicle efficiency. Therefore, understanding the importance of magnets in EV motors is essential for stakeholders aiming to optimize vehicle performance and meet consumer expectations.

Challenges in Sourcing Rare Earth Materials

| Challenges | Impact |

|---|---|

| Geopolitical tensions | Supply chain disruptions |

| Environmental concerns | Regulatory hurdles |

| High extraction costs | Increased product prices |

| Limited reserves | Uncertainty in future supply |

The production of high-performance magnets often relies on rare earth materials, which are not only scarce but also concentrated in specific geographic regions.

Countries like China dominate the rare earth market, controlling a substantial portion of global production and processing capabilities.

This reliance on a limited number of suppliers creates vulnerabilities in the supply chain, particularly in times of geopolitical tensions or trade disputes. Additionally, the extraction and processing of rare earth materials can be environmentally damaging and socially contentious. Mining operations often lead to habitat destruction and pollution, raising ethical concerns among consumers and regulators alike.

As automakers increasingly prioritize sustainability, sourcing rare earth materials responsibly becomes a critical challenge that must be addressed within the EV motor magnet supply chain.

Environmental Impact of Magnet Production

The environmental implications of magnet production extend beyond the sourcing of raw materials.

From energy-intensive production methods to waste generation, the lifecycle of magnets poses various environmental challenges that must be managed effectively.

As awareness of climate change and environmental degradation grows, stakeholders in the EV industry are under increasing pressure to adopt sustainable practices throughout their supply chains. This includes exploring alternative materials that can reduce reliance on rare earth elements or investing in recycling technologies that can reclaim valuable materials from end-of-life products. By addressing these environmental concerns, manufacturers can not only enhance their corporate social responsibility but also align with consumer expectations for greener products.

Global Trade and Geopolitical Issues

The global trade landscape plays a crucial role in shaping the dynamics of the EV motor magnet supply chain. Geopolitical tensions can disrupt trade flows and create uncertainties for manufacturers reliant on specific regions for their raw materials. For instance, trade disputes between major economies can lead to tariffs or export restrictions that impact the availability and cost of rare earth materials.

Furthermore, as countries strive for technological independence and security in critical industries like electric mobility, there is a growing trend towards reshoring or diversifying supply chains. This shift may lead to increased investments in domestic mining and processing capabilities, but it also requires significant time and resources to develop alternative sources. Navigating these geopolitical complexities is essential for stakeholders aiming to build resilient supply chains that can withstand external shocks.

Supply Chain Disruptions and Shortages

Recent events have highlighted the fragility of global supply chains, with disruptions caused by factors such as pandemics, natural disasters, and geopolitical tensions leading to shortages across various industries. The EV motor magnet supply chain is no exception; manufacturers have faced challenges in securing timely deliveries of essential components due to these disruptions. Shortages in magnet supplies can have cascading effects on EV production timelines and overall market growth.

Automakers may be forced to delay vehicle launches or scale back production targets if they cannot secure sufficient quantities of high-performance magnets. As demand for electric vehicles continues to rise, addressing these supply chain vulnerabilities becomes paramount for ensuring a stable flow of components necessary for production.

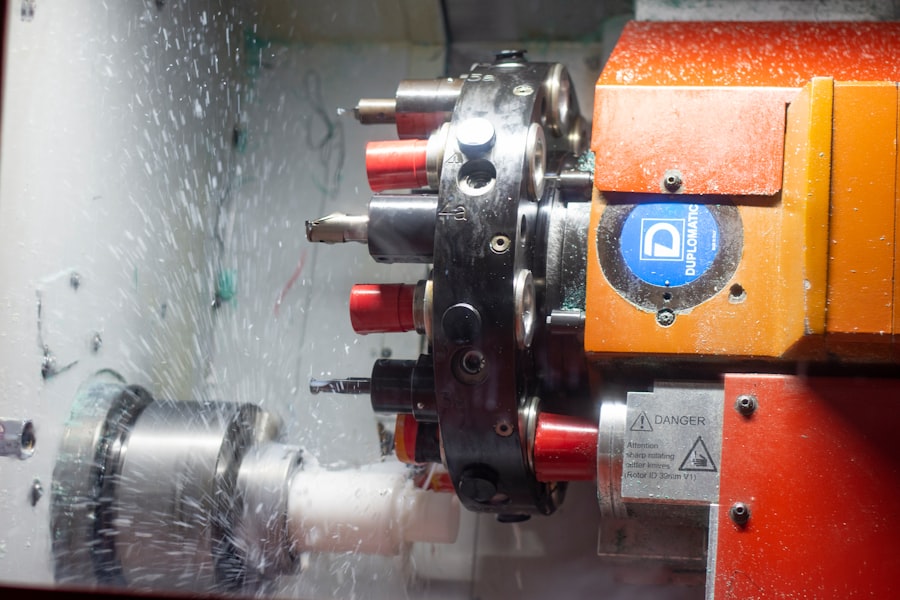

Technological Advancements in Magnet Production

In response to the challenges faced within the magnet supply chain, researchers and manufacturers are exploring innovative technologies aimed at improving magnet production processes. Advances in material science have led to the development of alternative magnet compositions that reduce reliance on rare earth elements while maintaining performance standards. Additionally, automation and digitalization are transforming manufacturing processes, enhancing efficiency and reducing waste.

These technological advancements not only promise to streamline production but also contribute to more sustainable practices within the industry. By embracing innovation, stakeholders can mitigate some of the risks associated with traditional magnet sourcing while positioning themselves competitively in an evolving market.

Strategies for Diversifying Magnet Suppliers

To build resilience within the EV motor magnet supply chain, manufacturers are increasingly recognizing the importance of diversifying their supplier base. Relying on a single source for critical materials poses significant risks; therefore, companies are actively seeking partnerships with multiple suppliers across different regions. This diversification strategy not only helps mitigate risks associated with geopolitical tensions but also fosters competition among suppliers, potentially leading to better pricing and quality standards.

Additionally, investing in local suppliers or developing domestic capabilities can enhance supply chain security while aligning with sustainability goals. By adopting a multifaceted approach to sourcing magnets, manufacturers can better navigate uncertainties while ensuring a steady flow of essential components.

Regulatory and Policy Considerations

Regulatory frameworks play a pivotal role in shaping the landscape of the EV motor magnet supply chain. Governments worldwide are increasingly implementing policies aimed at promoting sustainable practices within industries reliant on rare earth materials. These regulations may include stricter environmental standards for mining operations or incentives for recycling initiatives.

Moreover, as countries strive for energy independence and technological leadership in electric mobility, policymakers are likely to prioritize investments in domestic supply chains for critical materials like magnets. Stakeholders must stay informed about evolving regulations and actively engage with policymakers to advocate for supportive frameworks that facilitate sustainable sourcing practices while fostering innovation within the industry.

Future Outlook for EV Motor Magnet Supply Chain

The future outlook for the EV motor magnet supply chain is characterized by both challenges and opportunities. As demand for electric vehicles continues to grow exponentially, so too will the need for high-performance magnets that drive their efficiency and performance. However, navigating the complexities of sourcing rare earth materials while addressing environmental concerns will remain a significant challenge.

In response to these challenges, stakeholders are likely to invest heavily in research and development aimed at creating alternative materials and improving manufacturing processes. Additionally, as global trade dynamics evolve, companies will need to remain agile in adapting their supply chains to mitigate risks associated with geopolitical tensions. Ultimately, the success of the EV motor magnet supply chain will depend on collaboration among manufacturers, suppliers, policymakers, and researchers.

By working together towards common goals—such as sustainability, innovation, and resilience—stakeholders can ensure that the future of electric mobility is not only viable but also environmentally responsible.

The supply chain for EV motor magnets is a critical component in the production of electric vehicles, as it directly impacts the availability and cost of these essential parts. A related article on this topic can be found on Real Lore and Order, which delves into the complexities and challenges faced by manufacturers in securing a steady supply of rare earth materials necessary for magnet production. For more insights, you can read the full article by visiting this link. This resource provides a comprehensive overview of the current state of the EV motor magnet supply chain and explores potential solutions to mitigate supply disruptions.

WATCH THIS! They Can Shut Down Your World Overnight. This Is The Choke Point Controlling Everything!

FAQs

What is the EV motor magnet supply chain?

The EV motor magnet supply chain refers to the process of sourcing, manufacturing, and distributing the magnets used in electric vehicle (EV) motors.

What are the key components of the EV motor magnet supply chain?

The key components of the EV motor magnet supply chain include raw material extraction, magnet manufacturing, assembly into EV motors, and distribution to EV manufacturers.

What are the primary types of magnets used in EV motors?

The primary types of magnets used in EV motors are neodymium (NdFeB) magnets and ferrite (FeNdB) magnets.

Where are the raw materials for EV motor magnets sourced from?

The raw materials for EV motor magnets, such as neodymium and other rare earth elements, are primarily sourced from countries like China, Australia, and the United States.

What are the environmental and ethical concerns related to the EV motor magnet supply chain?

The EV motor magnet supply chain has raised concerns about environmental impact, as well as ethical issues related to labor practices and human rights in the mining and processing of raw materials.

How is the EV motor magnet supply chain evolving to meet the growing demand for EVs?

The EV motor magnet supply chain is evolving through efforts to diversify raw material sourcing, improve recycling and reuse of magnets, and develop alternative magnet technologies to reduce reliance on rare earth elements.