Copper has emerged as a pivotal material in the realm of semiconductor manufacturing, playing a crucial role in the development of modern electronic devices. Its unique properties, including excellent electrical conductivity, thermal conductivity, and malleability, have made it a preferred choice for interconnects in integrated circuits. As the demand for faster and more efficient electronic devices continues to rise, the semiconductor industry has increasingly turned to copper to meet these challenges.

The transition from aluminum to copper interconnects marked a significant milestone in semiconductor technology, enabling the miniaturization of components and enhancing overall performance. The adoption of copper in semiconductor manufacturing is not merely a trend; it represents a fundamental shift in how electronic devices are designed and produced. With the continuous scaling down of transistors and the push towards more compact and powerful chips, copper’s superior conductivity allows for reduced resistive losses and improved signal integrity.

Key Takeaways

- Copper enhances semiconductor performance due to its superior electrical conductivity and reliability.

- Advanced copper deposition techniques are critical for overcoming manufacturing challenges.

- Environmental considerations are increasingly important in copper semiconductor production.

- Copper plays a vital role in enabling technologies like 5G, AI, and IoT.

- The future of semiconductor manufacturing relies heavily on continued innovations in copper usage.

The Benefits of Using Copper in Semiconductor Manufacturing

One of the most significant advantages of using copper in semiconductor manufacturing is its exceptional electrical conductivity. Copper boasts a conductivity level that is nearly twice that of aluminum, which was the traditional choice for interconnects. This enhanced conductivity translates into lower resistive losses, allowing for faster signal transmission and improved overall performance of semiconductor devices.

As electronic components become increasingly miniaturized, the need for materials that can efficiently conduct electricity without generating excessive heat becomes paramount. Copper meets this requirement admirably, making it an ideal candidate for high-performance applications. In addition to its electrical properties, copper also offers superior thermal conductivity.

This characteristic is particularly important in semiconductor manufacturing, where heat dissipation is a critical factor in maintaining device reliability and performance. Efficient heat management ensures that semiconductor devices operate within safe temperature ranges, thereby prolonging their lifespan and enhancing their functionality. Furthermore, copper’s malleability allows for intricate designs and configurations, enabling manufacturers to create complex interconnect structures that optimize space and performance within integrated circuits.

The Challenges of Using Copper in Semiconductor Manufacturing

Despite its numerous advantages, the use of copper in semiconductor manufacturing is not without challenges. One of the primary concerns is copper’s susceptibility to electromigration, a phenomenon where metal atoms migrate under the influence of an electric field. This migration can lead to the formation of voids and hillocks within interconnects, ultimately compromising the integrity and reliability of semiconductor devices.

As transistors continue to shrink in size, the impact of electromigration becomes more pronounced, necessitating innovative solutions to mitigate this issue. Another challenge associated with copper is its tendency to diffuse into silicon substrates. This diffusion can adversely affect the electrical properties of the semiconductor material, leading to performance degradation.

To address this concern, manufacturers have developed barrier layers that prevent copper from migrating into silicon. However, these barrier layers introduce additional complexity into the manufacturing process and can impact overall device performance. As the industry strives for greater efficiency and miniaturization, finding effective ways to manage these challenges remains a top priority for semiconductor manufacturers.

The Future of Copper in Semiconductor Manufacturing

| Metric | Current Status | Projected 5-Year Growth | Key Challenges | Opportunities |

|---|---|---|---|---|

| Copper Usage in Semiconductor Wafers (tons/year) | Approximately 1,200 | +15% | Material purity and contamination control | Advanced interconnect technologies |

| Yield Improvement Due to Copper Interconnects (%) | Current average: 85% | Expected increase to 92% | Integration with new materials and processes | Enhanced device performance and reliability |

| Cost Reduction in Manufacturing (%) | Baseline | Up to 10% reduction | Initial investment in copper processing equipment | Lower resistance and power consumption |

| Adoption Rate of Copper Interconnects in New Chips (%) | 70% | Projected 90% | Compatibility with emerging semiconductor nodes | Scalability for smaller process nodes |

| Environmental Impact Reduction (%) | Current initiatives reducing waste by 20% | Target 35% reduction | Recycling and sustainable sourcing | Green manufacturing processes |

Looking ahead, the future of copper in semiconductor manufacturing appears promising, driven by ongoing advancements in technology and materials science. As the demand for smaller, faster, and more efficient electronic devices continues to grow, researchers are exploring new ways to enhance copper’s performance while addressing its inherent challenges. Innovations in alloying techniques and surface treatments are being investigated to improve copper’s resistance to electromigration and diffusion, ensuring its viability as a key material in next-generation semiconductor devices.

Moreover, as emerging technologies such as quantum computing and advanced AI applications gain traction, the need for high-performance interconnects will only intensify. Copper’s unique properties position it well to meet these demands, provided that ongoing research continues to address its limitations. The semiconductor industry is poised for a transformative era where copper will play an integral role in shaping the future of electronic devices, paving the way for unprecedented advancements in technology.

Advancements in Copper Deposition Techniques

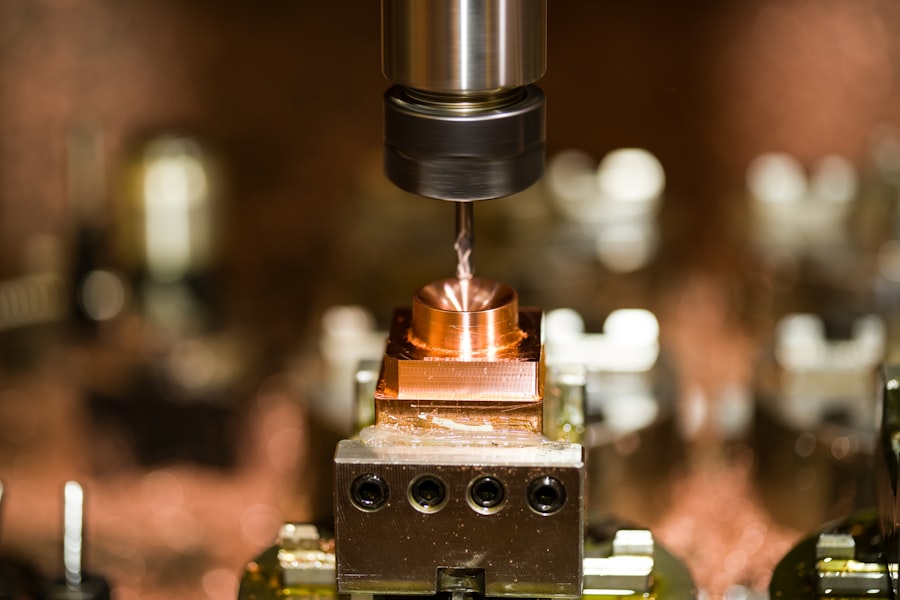

The evolution of copper deposition techniques has been instrumental in enhancing its application within semiconductor manufacturing. Traditional methods such as physical vapor deposition (PVD) have been widely used; however, they often fall short when it comes to achieving the fine features required for modern integrated circuits. In response to this challenge, researchers have developed advanced techniques such as electrochemical deposition (ECD) and atomic layer deposition (ALD).

These methods allow for precise control over film thickness and uniformity, ensuring that copper interconnects meet the stringent requirements of contemporary semiconductor designs. Electrochemical deposition has gained particular attention due to its ability to fill high-aspect-ratio features effectively. This technique enables manufacturers to deposit copper into narrow trenches and vias with exceptional precision, addressing one of the critical challenges posed by miniaturization.

Additionally, advancements in ALD have opened new avenues for creating ultra-thin copper films with controlled morphology and composition. These innovations not only enhance the performance of copper interconnects but also contribute to more sustainable manufacturing processes by reducing material waste.

The Impact of Copper on Semiconductor Performance

Copper’s influence on semiconductor performance extends beyond its electrical and thermal properties; it also plays a vital role in determining overall device reliability and longevity. The integration of copper interconnects has led to significant improvements in signal integrity, allowing for faster data transmission rates and reduced latency in electronic devices. As applications become increasingly data-intensive—such as those found in cloud computing and high-speed networking—the need for reliable interconnects becomes paramount.

Moreover, copper’s ability to dissipate heat effectively contributes to enhanced thermal management within semiconductor devices. Efficient heat dissipation not only prevents overheating but also minimizes the risk of thermal-induced failures that can compromise device performance. As manufacturers continue to push the boundaries of miniaturization and performance optimization, copper’s role as a critical enabler of high-performance semiconductor technology cannot be overstated.

Environmental Considerations in Copper Semiconductor Manufacturing

As the semiconductor industry grapples with environmental concerns, the sustainability of materials used in manufacturing processes has come under scrutiny. Copper is often viewed as a more environmentally friendly option compared to other metals due to its recyclability and lower energy consumption during extraction and processing. The ability to recycle copper effectively reduces waste and minimizes the environmental impact associated with mining new materials.

However, challenges remain regarding the environmental footprint of copper production and processing. The extraction of copper ore can lead to habitat destruction and pollution if not managed responsibly. Additionally, the energy-intensive nature of some manufacturing processes raises questions about sustainability.

To address these concerns, the industry is increasingly focusing on developing greener practices that prioritize resource efficiency and minimize environmental impact throughout the entire lifecycle of semiconductor manufacturing.

Copper’s Role in Advancing Semiconductor Technology

Copper’s contributions extend beyond its immediate applications; it plays a crucial role in advancing semiconductor technology as a whole. The transition from aluminum to copper interconnects marked a significant leap forward in chip design, enabling higher levels of integration and performance that were previously unattainable. This shift has paved the way for innovations such as system-on-chip (SoC) designs and multi-core processors that power today’s most advanced electronic devices.

Furthermore, as researchers explore new materials and architectures for future semiconductors—such as 2D materials and quantum dots—copper remains a foundational element due to its compatibility with existing manufacturing processes. Its versatility allows it to be integrated into various emerging technologies while maintaining performance standards that meet industry demands. As semiconductor technology continues to evolve, copper will undoubtedly remain at the forefront of innovation.

The Role of Copper in 5G and Beyond

The rollout of 5G technology represents a significant milestone in telecommunications, promising faster data speeds and lower latency for users worldwide. Copper plays an essential role in this transition by serving as a reliable conductor for high-frequency signals required by 5G networks. Its excellent electrical properties enable efficient signal transmission over short distances, making it an ideal choice for base stations and other critical infrastructure components.

As 5G networks expand and evolve into future generations—such as 6G—copper’s role will likely become even more pronounced. The increasing demand for high-speed connectivity will necessitate robust interconnect solutions capable of handling vast amounts of data traffic while maintaining signal integrity. Copper’s proven track record in supporting advanced communication technologies positions it as a key player in shaping the future landscape of telecommunications.

Copper’s Role in Emerging Technologies such as AI and IoT

The rise of artificial intelligence (AI) and the Internet of Things (IoT) has ushered in a new era of technological innovation characterized by interconnected devices and data-driven applications. Copper’s unique properties make it an indispensable material for supporting these emerging technologies. In AI applications, where rapid data processing is essential, copper interconnects facilitate high-speed communication between processors and memory units, enabling efficient machine learning algorithms.

Similarly, IoT devices rely on reliable connectivity to transmit data seamlessly across networks. Copper’s ability to provide stable connections ensures that IoT devices can communicate effectively with one another and with centralized systems. As these technologies continue to proliferate across various industries—from smart homes to industrial automation—copper will remain a vital component driving their success.

The Promising Future of Copper in Semiconductor Manufacturing

In conclusion, copper’s role in semiconductor manufacturing is multifaceted and continues to evolve alongside technological advancements. Its exceptional electrical and thermal properties make it an indispensable material for modern electronic devices, while ongoing research seeks to address challenges such as electromigration and diffusion. As manufacturers explore innovative deposition techniques and sustainable practices, copper’s contributions will only grow more significant.

Looking ahead, the future of copper in semiconductor manufacturing appears bright, with its applications extending into emerging technologies such as 5G, AI, and IoT. As the industry embraces new challenges and opportunities, copper will undoubtedly remain at the forefront of innovation—shaping the next generation of electronic devices while contributing to a more sustainable future for semiconductor manufacturing.

The future of copper in semiconductor manufacturing is a topic of great interest, especially as the industry seeks to enhance performance and efficiency.