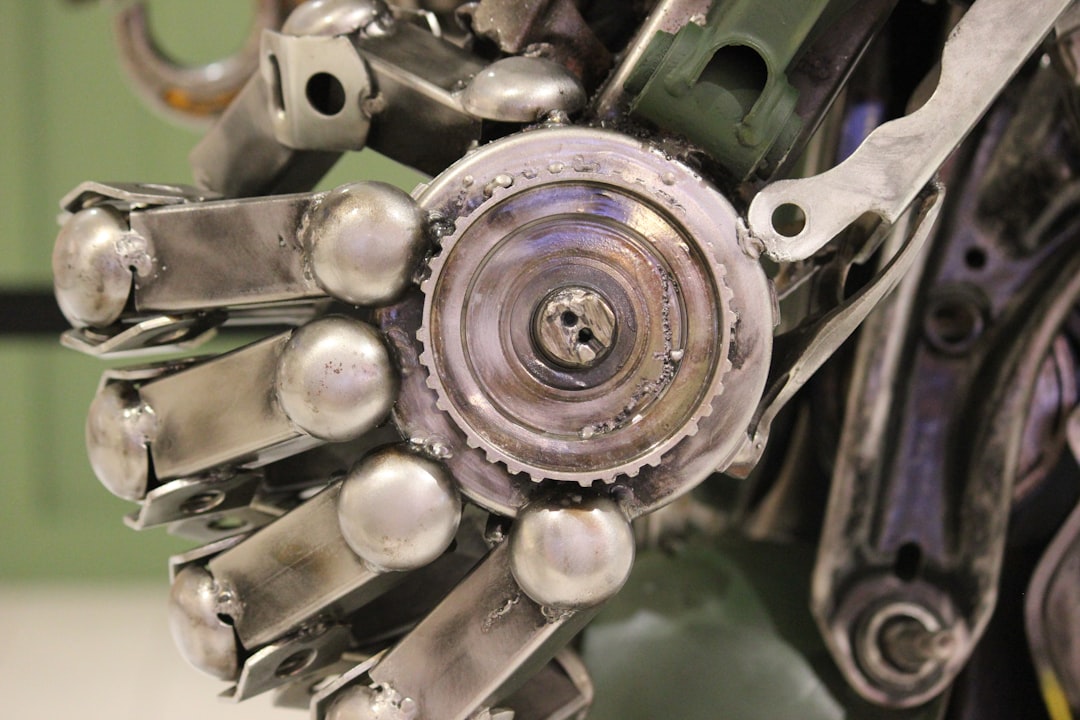

Pin slot epicyclic gears represent a sophisticated mechanism within the realm of gear systems, characterized by their unique arrangement and functionality. These gears consist of a central sun gear, surrounding planet gears, and an outer ring gear, all of which work in unison to transmit motion and torque. The defining feature of pin slot epicyclic gears is the use of pins that engage with slots in the planet gears, allowing for a more efficient transfer of power and enabling a compact design.

This configuration not only enhances the gear’s ability to handle varying loads but also contributes to its versatility in different applications. The operational principle of pin slot epicyclic gears is rooted in their ability to provide multiple gear ratios within a single assembly. By adjusting the input and output connections, these gears can achieve different speeds and torques, making them invaluable in applications where space is limited but performance is critical.

The design allows for smooth transitions between gear ratios, which is particularly beneficial in automotive and aerospace industries where efficiency and reliability are paramount.

Key Takeaways

- Pin slot epicyclic gears are specialized gear systems featuring pins and slots for smooth power transmission.

- They offer advantages like compact design, high efficiency, and reduced wear compared to traditional gears.

- Commonly used in automotive transmissions, robotics, and aerospace applications due to their reliability and performance.

- Design considerations include material selection, slot geometry, and load distribution to optimize gear function.

- Ongoing innovations focus on improving durability, reducing noise, and enhancing manufacturing techniques for future applications.

The History of Pin Slot Epicyclic Gears

The evolution of pin slot epicyclic gears can be traced back to the early days of mechanical engineering, where the need for efficient power transmission systems became increasingly apparent. The concept of epicyclic gearing itself dates back to ancient civilizations, with early examples found in Greek and Roman machinery. However, the specific design of pin slot epicyclic gears emerged much later, as engineers sought to refine existing gear systems to improve their performance and adaptability.

In the 20th century, advancements in materials science and manufacturing techniques paved the way for the widespread adoption of pin slot epicyclic gears. The introduction of high-strength alloys and precision machining allowed for the creation of more compact and durable gear systems. This period marked a significant turning point, as industries began to recognize the advantages of these gears in applications ranging from automotive transmissions to robotics.

As technology progressed, so did the complexity and efficiency of pin slot epicyclic gear designs, leading to their integration into modern machinery.

Advantages of Pin Slot Epicyclic Gears

One of the primary advantages of pin slot epicyclic gears is their ability to provide high torque density in a compact form factor. This characteristic makes them particularly appealing for applications where space constraints are a significant concern. Unlike traditional gear systems that may require larger assemblies to achieve similar torque outputs, pin slot designs can deliver impressive performance without occupying excessive space.

This efficiency is crucial in industries such as aerospace, where weight reduction is often a key design consideration. Another notable benefit is the smooth operation and reduced noise levels associated with pin slot epicyclic gears. The engagement of pins within slots allows for a more stable interaction between components, minimizing backlash and vibrations that can lead to wear over time.

This feature not only enhances the longevity of the gear system but also contributes to improved overall performance. Additionally, the ability to achieve multiple gear ratios within a single assembly further enhances their versatility, making them suitable for a wide range of applications.

Applications of Pin Slot Epicyclic Gears

Pin slot epicyclic gears find applications across various industries due to their unique characteristics and advantages. In the automotive sector, they are commonly used in automatic transmissions, where the need for seamless gear shifting is paramount. The ability to provide multiple gear ratios allows for smoother acceleration and improved fuel efficiency, making them an integral part of modern vehicle design.

Beyond automotive applications, pin slot epicyclic gears are also utilized in robotics and automation systems. Their compact size and high torque output make them ideal for robotic arms and other machinery that require precise movement and control. In aerospace engineering, these gears are employed in flight control systems and landing gear mechanisms, where reliability and performance are critical.

The versatility of pin slot epicyclic gears ensures that they continue to play a vital role in advancing technology across diverse fields.

How Pin Slot Epicyclic Gears Work

| Parameter | Value | Unit | Description |

|---|---|---|---|

| Number of Planet Gears | 3 | count | Number of planet gears in the epicyclic gear set |

| Sun Gear Teeth | 20 | teeth | Number of teeth on the sun gear |

| Ring Gear Teeth | 60 | teeth | Number of teeth on the ring gear |

| Planet Gear Teeth | 20 | teeth | Number of teeth on each planet gear |

| Gear Ratio (Ring/Sun) | 3 | ratio | Speed ratio between ring and sun gear |

| Slot Width | 5 | mm | Width of the pin slot in the planet gear |

| Slot Length | 15 | mm | Length of the pin slot in the planet gear |

| Pin Diameter | 4 | mm | Diameter of the pin engaging the slot |

| Maximum Torque Capacity | 120 | Nm | Maximum torque the gear set can transmit |

| Material | Alloy Steel | – | Material used for gears and pins |

The operation of pin slot epicyclic gears is based on a combination of rotational motion and mechanical advantage. At the heart of this system lies the sun gear, which serves as the primary input source. As the sun gear rotates, it drives the planet gears that are mounted on pins within slots on the outer ring gear.

This arrangement allows for a unique interaction between components, enabling the transfer of motion and torque in an efficient manner. The configuration allows for different modes of operation depending on how the input and output are connected. By fixing either the sun gear or the ring gear while allowing the other components to rotate freely, various gear ratios can be achieved.

This flexibility is one of the key reasons why pin slot epicyclic gears are favored in applications requiring adaptability and precision. The smooth engagement between pins and slots further enhances performance by reducing friction and wear during operation.

Design Considerations for Pin Slot Epicyclic Gears

When designing pin slot epicyclic gears, several critical factors must be taken into account to ensure optimal performance and longevity. One primary consideration is material selection; high-strength materials are essential to withstand the stresses encountered during operation. Engineers often opt for alloys that offer a balance between strength and weight, ensuring that the gear system remains both durable and lightweight.

Another important aspect is the geometry of the pins and slots themselves. The design must allow for smooth engagement while minimizing backlash, which can lead to inefficiencies and increased wear over time.

Additionally, lubrication plays a crucial role in maintaining performance; proper lubrication reduces friction between moving parts, enhancing efficiency and extending the lifespan of the gear system.

Comparing Pin Slot Epicyclic Gears to Other Gear Systems

When comparing pin slot epicyclic gears to other gear systems, several distinct advantages become apparent. Traditional spur gears, for instance, may offer simplicity but often lack the compactness and versatility found in pin slot designs. Spur gears typically require larger assemblies to achieve similar torque outputs, making them less suitable for applications with stringent space constraints.

In contrast, planetary gear systems provide some similarities to pin slot designs but may not offer the same level of efficiency or smoothness in operation. While both systems can achieve multiple gear ratios, pin slot epicyclic gears excel in applications requiring rapid shifts between ratios without compromising performance.

Challenges and Limitations of Pin Slot Epicyclic Gears

Despite their numerous advantages, pin slot epicyclic gears are not without challenges and limitations. One significant concern is their sensitivity to misalignment; even minor deviations can lead to increased wear or failure of components over time. This necessitates precise installation and alignment during assembly, which can be a time-consuming process.

Additionally, while pin slot designs excel in compactness and efficiency, they may not always be suitable for high-load applications where extreme durability is required. In such cases, alternative gear systems may be preferred due to their ability to handle greater forces without compromising performance. Engineers must carefully evaluate application requirements when selecting gear systems to ensure optimal performance and reliability.

Innovations and Developments in Pin Slot Epicyclic Gears

The field of pin slot epicyclic gears continues to evolve with ongoing innovations aimed at enhancing performance and expanding their applicability. Recent developments have focused on improving materials used in construction, with advancements in composites and alloys leading to lighter yet stronger components. These innovations not only enhance durability but also contribute to overall efficiency by reducing weight.

Furthermore, advancements in computer-aided design (CAD) software have enabled engineers to simulate various operating conditions more effectively than ever before. This capability allows for more precise optimization of gear geometry and material selection, resulting in improved performance characteristics tailored to specific applications. As technology progresses, it is likely that new designs will emerge that further push the boundaries of what pin slot epicyclic gears can achieve.

Maintenance and Care of Pin Slot Epicyclic Gears

Proper maintenance is essential for ensuring the longevity and optimal performance of pin slot epicyclic gears. Regular inspections should be conducted to identify any signs of wear or misalignment that could compromise functionality. Lubrication is another critical aspect; using appropriate lubricants helps reduce friction between moving parts while preventing overheating during operation.

In addition to routine maintenance tasks, operators should also be aware of environmental factors that could impact gear performance. Exposure to contaminants such as dust or moisture can lead to premature wear or failure if not addressed promptly. Implementing protective measures such as seals or covers can help mitigate these risks, ensuring that pin slot epicyclic gears continue to operate efficiently over time.

Future Trends in Pin Slot Epicyclic Gears

Looking ahead, several trends are likely to shape the future development of pin slot epicyclic gears. One prominent direction is the increasing integration of smart technologies into mechanical systems. As industries move towards automation and data-driven decision-making processes, incorporating sensors into gear systems could provide real-time monitoring capabilities that enhance performance and predictive maintenance strategies.

Additionally, sustainability considerations are becoming increasingly important across all sectors. Future designs may focus on reducing material waste during production while also exploring eco-friendly alternatives for lubricants and other components. As engineers continue to innovate within this space, it is expected that pin slot epicyclic gears will evolve further, maintaining their relevance in an ever-changing technological landscape while meeting new demands for efficiency and sustainability.

Pin slot epicyclic gears are a fascinating topic in mechanical engineering, particularly due to their unique ability to provide high torque and compact design. For those interested in exploring more about the applications and mechanics of such gear systems, you can check out a related article on the subject at Real Lore and Order. This resource delves into various gear mechanisms and their practical uses, offering valuable insights for both enthusiasts and professionals in the field.

WATCH THIS! 🚨 Divers Found THIS at the Bottom of the Sea—Scientists Still Can’t Explain It

FAQs

What are pin slot epicyclic gears?

Pin slot epicyclic gears are a type of planetary gear system where the gears have pins that fit into slots, allowing for smooth transmission of motion and torque. This design helps in reducing friction and wear while maintaining precise gear engagement.

How do pin slot epicyclic gears work?

In pin slot epicyclic gears, the pins on one gear mesh with the slots on another, enabling relative motion between the gears. The arrangement allows the planet gears to rotate around the sun gear while also revolving within the ring gear, providing compact and efficient power transmission.

What are the advantages of using pin slot epicyclic gears?

Advantages include high torque transmission in a compact space, smooth operation due to reduced sliding friction, improved load distribution, and enhanced durability. They are also capable of handling complex motion profiles and can be designed for various gear ratios.

Where are pin slot epicyclic gears commonly used?

These gears are commonly used in automotive transmissions, robotics, aerospace mechanisms, and industrial machinery where compact, efficient, and reliable gear systems are required.

What materials are typically used for pin slot epicyclic gears?

Materials often include hardened steel for durability and wear resistance, though depending on the application, alloys, composites, or specialized coatings may be used to enhance performance and reduce friction.

How do pin slot epicyclic gears differ from traditional epicyclic gears?

The key difference lies in the engagement mechanism: pin slot epicyclic gears use pins and slots for meshing, which reduces sliding friction and wear compared to traditional tooth-to-tooth contact in standard epicyclic gears.

Can pin slot epicyclic gears be customized for specific applications?

Yes, these gears can be designed with varying numbers of pins, slot shapes, and gear sizes to meet specific torque, speed, and space requirements for different applications.

What maintenance is required for pin slot epicyclic gears?

Regular lubrication, inspection for wear or damage, and ensuring proper alignment are essential maintenance practices to ensure longevity and optimal performance of pin slot epicyclic gears.