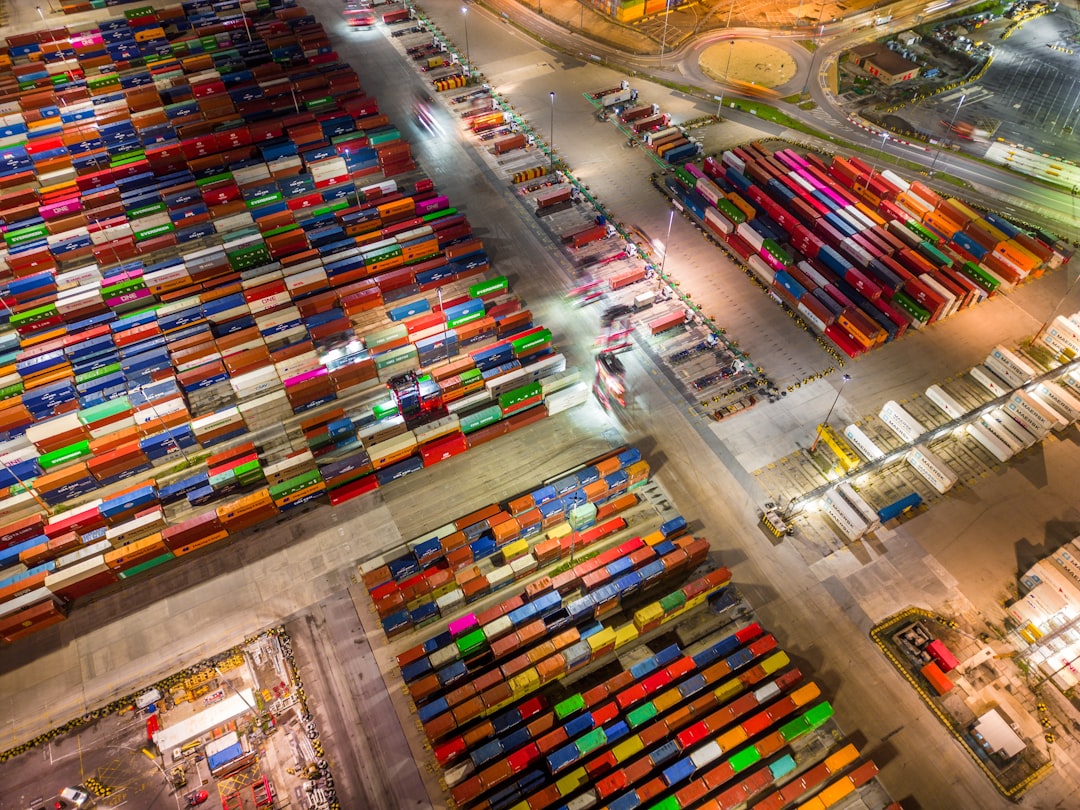

The intricate network of German industry, a finely tuned engine of global commerce, is currently experiencing a significant period of disruption. The days of predictable, seamless supply chains, once the bedrock of German manufacturing prowess, are being challenged by a growing fragmentation. This fragmentation is not a singular event but rather a multifaceted phenomenon, arising from geopolitical shifts, technological advancements, and evolving societal expectations. For businesses operating within and reliant upon Germany’s economic powerhouse, understanding these challenges and identifying viable solutions is paramount to navigating the complex currents of the modern global economy.

The established architecture of global supply chains, particularly those deeply intertwined with German manufacturing, is undergoing a seismic recalibration. For decades, a model of highly optimized, lean production, often relying on extended manufacturing networks and just-in-time delivery, served as the backbone of German industrial success. This system, while efficient in stable times, now faces considerable pressure from a confluence of factors that are fundamentally redrawing the map of global trade and supply. The recent report highlights the impact of [Germany factory closures] on the European economy.

Geopolitical Fault Lines and Trade Realignments

The current geopolitical landscape is akin to a tempestuous sea, with rising tides of protectionism and shifting alliances creating significant turbulence for established trade routes. The long-standing reliance on specific regions for crucial raw materials or manufacturing components is now viewed with increased scrutiny. Sanctions, trade disputes, and the desire for greater national economic resilience are leading to a strategic decoupling, forcing German industries to re-evaluate their dependencies. The erstwhile predictable flow of goods is now subject to the uncertainties of international relations, turning once stable arteries of commerce into precarious pathways.

The Digital Deluge: Technological Disruption and Data Silos

While digital transformation has been a celebrated driver of efficiency, it has also introduced its own layer of complexity. The sheer volume of data generated across a dispersed supply chain, coupled with a lack of interoperability between disparate digital systems, can create invisible walls. Information does not flow freely; instead, it often resides in isolated silos, hindering real-time visibility and predictive analytics. This digital fragmentation means that critical insights, necessary for agile decision-making, may be obscured, leaving businesses navigating in fog, unable to perceive the full scope of their operational environment.

The Sustainability Imperative: Environmental and Social Pressures

A growing awareness of environmental and social responsibilities is no longer a peripheral concern but a central tenet of modern business. Consumers, investors, and regulators are demanding greater transparency and accountability throughout the entire supply chain. This translates to scrutiny of sourcing practices, labor conditions, and carbon footprints, often extending far beyond a company’s immediate suppliers. Meeting these stringent demands requires a level of insight and control that can be difficult to achieve when supply chains are fragmented and lack comprehensive oversight. The pressure to build greener, more ethical supply chains is a powerful force reshaping existing networks.

In recent discussions about the challenges facing the German economy, the issue of supply chain fragmentation has emerged as a critical concern. A related article that delves deeper into this topic can be found at Real Lore and Order, where it explores the implications of disrupted supply chains on various sectors and suggests potential strategies for mitigating these challenges. Understanding the dynamics of supply chain fragmentation is essential for businesses looking to navigate the complexities of the current economic landscape.

H2: Manifestations of Fragmentation: The Everyday Impact on German Industry

The abstract concepts of geopolitical shifts and technological advancements translate into concrete challenges that ripple through the daily operations of German businesses. These challenges are not isolated incidents but form a pervasive atmosphere of uncertainty that impacts production, logistics, and ultimately, profitability.

Cascading Disruptions and Unforeseen Bottlenecks

When one element of a highly interconnected supply chain falters, the impact can cascade through the entire system. A shortage of a key semiconductor in Asia, for instance, can bring an automobile assembly line in Bavaria to a standstill. These bottlenecks are no longer rare occurrences but have become a recurring theme, akin to a chronic ailment affecting the heart of industrial production. The ripple effect of a disruption in one corner of the globe can be felt acutely in the workshops and factories of Germany.

Rising Costs and Inflationary Pressures

The fragmentation of supply chains often leads to increased costs. Re-routing shipments, diversifying sourcing, and investing in new technologies to enhance visibility all come with a price tag. Furthermore, reduced availability of certain components can drive up prices due to scarcity. These escalating costs are then passed on through the value chain, contributing to broader inflationary pressures within the German economy. The invisible hand of the market, when faced with a fractured supply network, often exerts a more forceful and expensive grip.

Diminished Resilience and Increased Vulnerability

A fragmented supply chain, by its very nature, is often less resilient. The reliance on a multitude of disparate, less integrated nodes makes the entire system more vulnerable to shocks. If one link in a long chain breaks, the entire structure can be compromised. This diminished resilience leaves German industries more exposed to unforeseen events, from natural disasters and pandemics to cyberattacks and political instability. The once robust edifice of German manufacturing now finds itself built on a foundation that feels less solid, more prone to tremors.

H2: Navigating the Labyrinth: Proactive Strategies for German Businesses

The challenges posed by supply chain fragmentation necessitate a shift from reactive problem-solving to proactive strategic planning. German industries must adapt their operational models to build more robust and agile networks that can withstand volatility. This requires a fundamental rethinking of how goods and information flow from origin to destination.

Embracing Diversification and Nearshoring/Reshoring

A critical strategy to mitigate the risks of concentrated dependencies is to diversify sourcing and manufacturing locations. This involves exploring options for nearshoring, bringing production closer to home markets (e.g., within Europe), and even reshoring, bringing manufacturing back to Germany. While these shifts may entail higher immediate costs, they offer greater control, reduced lead times, and enhanced resilience against distant geopolitical disruptions. This is akin to strengthening the root system of a tree, making it less susceptible to being uprooted by a distant storm.

Investing in Digital Transformation and End-to-End Visibility

True digital transformation is not just about adopting new technologies, but about leveraging them to create a holistic, interconnected view of the entire supply chain. This involves investing in integrated platforms, IoT devices, and advanced analytics to achieve real-time visibility from raw material sourcing to final customer delivery. Such a system acts as a sophisticated early warning system, allowing businesses to identify potential disruptions before they escalate into major problems. The goal is to transform the fragmented digital landscape into a seamless, intelligent network, allowing for informed navigation even in complex terrain.

Cultivating Stronger Supplier Relationships and Collaboration

The traditional transactional approach to supplier management is no longer sufficient. German businesses need to cultivate deeper, more collaborative relationships with their key suppliers. This involves sharing information, engaging in joint risk assessments, and fostering a spirit of mutual dependency. By treating suppliers as strategic partners, rather than mere vendors, companies can build more resilient and adaptable supply networks. This is about moving from a battlefield of individual actors to a cohesive unit working in concert, where each member understands their role and contribution to the collective success.

H2: Building Future-Proof Supply Chains: The Role of Innovation and Technology

The path forward for German supply chains lies in embracing innovation and leveraging cutting-edge technologies to foster adaptability and resilience. This requires a forward-thinking approach to infrastructure, data management, and operational processes.

The Power of AI and Machine Learning for Predictive Analytics

Artificial intelligence (AI) and machine learning (ML) are becoming indispensable tools in managing complex supply chains. These technologies can analyze vast datasets to identify patterns, predict demand fluctuations, and anticipate potential disruptions with remarkable accuracy. By harnessing the predictive power of AI/ML, businesses can shift from a reactive mode of dealing with crises to a proactive approach of preventing them. This is like having a seasoned navigator who can read the ocean currents and weather patterns, steering the ship clear of impending storms.

Blockchain for Enhanced Transparency and Traceability

Blockchain technology offers a decentralized, immutable ledger that can revolutionize supply chain transparency and traceability. By recording every transaction and movement of goods on a secure, shared ledger, blockchain can provide an unparalleled level of trust and accountability across all parties involved. This verifiable audit trail is crucial for meeting sustainability mandates, combating counterfeit goods, and ensuring product integrity. It’s akin to a crystal-clear magnifying glass that reveals the entire journey of a product, leaving no room for doubt or deception.

The Autonomous Revolution: Robotics and Automation in Logistics

The increasing adoption of robotics and automation in warehousing and logistics promises to enhance efficiency and reduce reliance on manual processes, which can be prone to human error and labor shortages. Autonomous vehicles, robotic picking systems, and automated sorting facilities can streamline operations, reduce turnaround times, and improve overall supply chain agility. This automation is akin to building a more robust and tireless army for the logistical battle, capable of operating with precision and speed.

In recent discussions about the challenges facing the German economy, the issue of supply chain fragmentation has emerged as a critical topic. This fragmentation not only affects production efficiency but also impacts the overall competitiveness of German industries on a global scale. For a deeper understanding of this complex issue, you can explore a related article that delves into the implications of supply chain disruptions and strategies for mitigation. To read more about it, visit this insightful piece that provides valuable perspectives on the current landscape.

H2: Conclusion: Charting a Course for German Industrial Resilience

| Metric | Value | Unit | Description |

|---|---|---|---|

| Number of Suppliers | 12,500 | Count | Total number of suppliers involved in German manufacturing supply chains |

| Average Supplier Distance | 450 | km | Average geographic distance between German manufacturers and their suppliers |

| Supply Chain Tiers | 4 | Levels | Average number of tiers in German manufacturing supply chains |

| Fragmentation Index | 0.68 | Index (0-1) | Measure of supply chain fragmentation, with 1 being highly fragmented |

| Lead Time Variability | 15 | % | Percentage variation in lead times due to fragmentation |

| Percentage of Domestic Suppliers | 55 | % | Share of suppliers located within Germany |

| Percentage of EU Suppliers | 30 | % | Share of suppliers located within the European Union but outside Germany |

| Percentage of Non-EU Suppliers | 15 | % | Share of suppliers located outside the European Union |

The fragmentation of German supply chains presents a formidable set of challenges, born from a confluence of global forces. However, for an industrial powerhouse with a rich history of innovation and adaptation, these challenges also represent an opportunity. By embracing diversification, investing in digital transformation, and fostering deeper collaboration, German businesses can not only navigate the current complexities but emerge stronger and more resilient. The journey ahead is not without its obstacles, but with strategic foresight and a commitment to embracing the future, the German industrial engine can continue to power its way through the shifting sands of global commerce. The current headwinds facing German supply chains are undeniable, but the inherent ingenuity and adaptability of its industries offer a clear pathway towards building a more robust and future-proof economic landscape. The future of German manufacturing depends on its ability to transform these challenges into a catalyst for reinvention.

WATCH THIS 🔴 SHOCKING: Why Germany’s Factory Exodus Is Permanent (Not Temporary)

FAQs

What is supply chain fragmentation?

Supply chain fragmentation refers to the breaking up of a supply chain into smaller, often geographically dispersed segments. This can lead to increased complexity in managing production, logistics, and coordination among different suppliers and manufacturers.

Why is supply chain fragmentation significant for Germany?

Germany is a major industrial and manufacturing hub with a complex network of suppliers and manufacturers. Fragmentation in its supply chains can impact efficiency, increase costs, and create vulnerabilities, especially in sectors like automotive and machinery.

What are the main causes of supply chain fragmentation in Germany?

Key causes include globalization, outsourcing of production to different countries, increased specialization of suppliers, and disruptions such as geopolitical tensions or the COVID-19 pandemic, which have exposed weaknesses in tightly interconnected supply chains.

How does supply chain fragmentation affect German industries?

Fragmentation can lead to delays, higher operational costs, reduced flexibility, and challenges in quality control. It may also increase the risk of supply shortages and impact Germany’s export-driven economy.

What measures are being taken to address supply chain fragmentation in Germany?

German companies and policymakers are focusing on diversifying suppliers, increasing local production capabilities, investing in digital supply chain management tools, and enhancing collaboration across the supply chain to improve resilience and reduce dependency on fragmented networks.