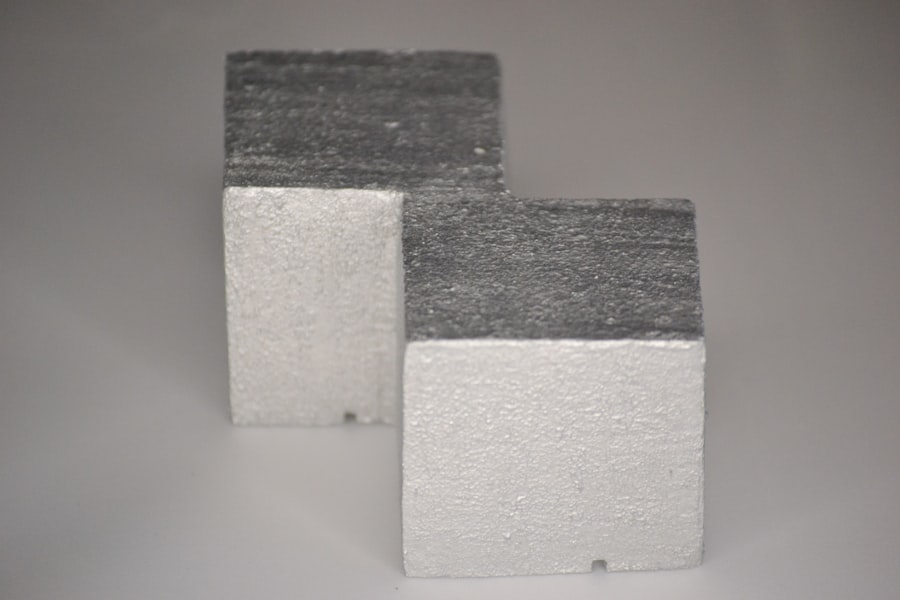

Egyptian granite is renowned for its durability and aesthetic appeal, making it a favored choice in construction and decorative applications. This natural stone, primarily composed of quartz, feldspar, and mica, exhibits a unique blend of strength and beauty. Its crystalline structure not only contributes to its resilience but also gives it a distinctive appearance, often characterized by vibrant colors and intricate patterns.

The geological formation of Egyptian granite, which has been shaped over millions of years, results in a material that can withstand significant wear and tear, making it ideal for both indoor and outdoor use. Moreover, the density and hardness of Egyptian granite present both advantages and challenges in drilling applications. While its toughness ensures longevity and resistance to environmental factors, it also requires specialized techniques and tools for effective drilling.

Understanding these properties is crucial for anyone looking to work with this stone, as it influences the choice of equipment, drilling methods, and overall project planning. The unique characteristics of Egyptian granite not only enhance its visual appeal but also dictate the precision required in any drilling endeavor.

Key Takeaways

- Understanding Egyptian granite’s hardness and composition is crucial for effective drilling.

- Using specialized tools and maintaining proper drill speed and pressure ensures precision.

- Proper cooling and lubrication prevent overheating and extend drill bit life.

- Preparing the work area and employing accurate hole placement techniques improve results.

- Following safety protocols and finishing methods enhances both safety and hole quality.

Selecting the Right Tools and Equipment for Precision Drilling

Choosing the appropriate tools and equipment is paramount when it comes to precision drilling in Egyptian granite. The hardness of the stone necessitates the use of high-quality diamond-tipped drill bits, which are specifically designed to cut through tough materials. These bits are engineered to withstand the intense friction generated during drilling, ensuring that they maintain their sharpness and effectiveness over time.

Additionally, a reliable drill with adjustable speed settings is essential, as different drilling tasks may require varying levels of power and control. In addition to drill bits and machines, other tools such as water cooling systems and vacuum attachments can significantly enhance the drilling process. Water cooling systems help to dissipate heat generated during drilling, preventing damage to both the drill bit and the granite itself.

Vacuum attachments assist in managing dust and debris, creating a cleaner work environment and improving visibility during the drilling process. By carefully selecting the right combination of tools and equipment, one can ensure a more efficient and precise drilling experience in Egyptian granite.

Preparing the Work Area for Precision Drilling

Preparation of the work area is a critical step that should not be overlooked when drilling into Egyptian granite. A well-organized workspace not only enhances safety but also improves efficiency during the drilling process. First and foremost, it is essential to clear the area of any unnecessary materials or obstacles that could impede movement or create hazards.

This includes removing loose stones, debris, or any other items that may pose a risk during operation. Furthermore, securing the granite slab is vital to ensure stability while drilling. Using clamps or a sturdy workbench can help hold the stone in place, preventing any unwanted movement that could lead to inaccuracies in hole placement.

Additionally, marking the intended drilling points with precision is crucial; this can be achieved using a pencil or chalk to create clear guidelines. By taking the time to prepare the work area thoroughly, one can set the stage for a successful drilling operation that minimizes errors and maximizes safety.

Techniques for Achieving Accurate Hole Placement in Egyptian Granite

Achieving accurate hole placement in Egyptian granite requires a combination of careful planning and precise execution. One effective technique involves using a template or jig to guide the drill bit during operation. This method not only helps maintain consistent spacing between holes but also ensures that each hole is drilled at the correct angle.

Templates can be made from various materials, including wood or plastic, and should be securely fastened to the granite surface before drilling begins. Another important technique is to start with a pilot hole. Drilling a small pilot hole at the marked location serves as a guide for larger drill bits, reducing the risk of wandering or misalignment during the drilling process.

This initial hole helps to stabilize the drill bit and provides a clear entry point for subsequent drilling. By employing these techniques, one can significantly enhance the accuracy of hole placement in Egyptian granite, leading to more professional results.

Mastering the Art of Controlling Drill Speed and Pressure

| Technique | Drill Type | Drill Diameter (mm) | Drilling Speed (mm/min) | Precision Level (mm) | Typical Use | Comments |

|---|---|---|---|---|---|---|

| Diamond Core Drilling | Diamond-tipped Core Drill | 50 – 150 | 5 – 15 | ±0.1 | Extracting cylindrical granite samples | High precision, minimal damage to surrounding stone |

| Water Jet Assisted Drilling | High-pressure Water Jet Drill | 30 – 100 | 10 – 20 | ±0.2 | Fine detail drilling and shaping | Reduces heat and dust, improves drill bit life |

| Rotary Percussion Drilling | Rotary Hammer Drill | 40 – 120 | 15 – 25 | ±0.5 | Rough drilling for block extraction | Faster but less precise, used in initial stages |

| Ultrasonic Drilling | Ultrasonic Drill with Abrasive Slurry | 10 – 50 | 1 – 5 | ±0.05 | Micro-drilling and intricate designs | Very high precision, slow process |

| Wire Saw Drilling | Diamond Wire Saw | Variable (wire thickness) | Variable | ±0.3 | Cutting large granite blocks | Used for block separation, not for holes |

Controlling drill speed and pressure is an essential skill when working with Egyptian granite. The hardness of this stone means that applying too much pressure can lead to overheating or even damage to both the drill bit and the granite itself. Conversely, insufficient pressure may result in ineffective drilling or prolonged operation times.

Therefore, finding the right balance is crucial for achieving optimal results. A good practice is to start with a lower speed setting and gradually increase it as needed. This allows for better control over the drilling process while minimizing heat buildup.

Additionally, maintaining consistent pressure throughout the operation is vital; applying steady pressure rather than fluctuating can help ensure a smooth drilling experience. By mastering these aspects of drill speed and pressure control, one can enhance both efficiency and precision when working with Egyptian granite.

Ensuring Proper Cooling and Lubrication During Drilling

Proper cooling and lubrication are critical components of successful drilling in Egyptian granite. The intense friction generated during drilling can lead to overheating, which not only affects the drill bit’s lifespan but can also compromise the integrity of the granite itself. To mitigate this risk, implementing a cooling system is essential.

Water is often used as a coolant during drilling operations; it helps dissipate heat while also reducing dust production. In addition to water cooling systems, using lubricants specifically designed for stone drilling can further enhance performance. These lubricants create a protective barrier between the drill bit and the granite surface, reducing friction and wear on both components.

Regularly applying coolant or lubricant throughout the drilling process ensures that temperatures remain manageable and that both the drill bit and granite maintain their integrity. By prioritizing cooling and lubrication, one can significantly improve drilling efficiency while prolonging tool life.

Overcoming Challenges and Obstacles in Egyptian Granite Drilling

Drilling into Egyptian granite presents several challenges that require careful consideration and strategic planning. One common obstacle is encountering variations in hardness within different sections of the stone. These inconsistencies can lead to uneven wear on drill bits or unexpected changes in drilling speed.

This approach allows for adjustments in technique or equipment based on observed variations. Another challenge often faced during drilling is managing dust and debris generated by the process.

Excessive dust not only creates visibility issues but can also pose health risks if inhaled. Utilizing vacuum attachments or water cooling systems can help mitigate these concerns by keeping the work area cleaner and safer. By proactively addressing these challenges, one can navigate potential obstacles more effectively, ensuring a smoother drilling experience in Egyptian granite.

Tips for Maintaining Drill Bit Sharpness and Longevity

Maintaining drill bit sharpness is crucial for achieving optimal performance when drilling into Egyptian granite. Dull bits not only slow down progress but can also lead to increased heat generation and potential damage to both the bit and the stone itself. One effective strategy for prolonging drill bit life is to regularly inspect them for signs of wear or damage.

If any issues are detected, sharpening or replacing bits promptly can prevent further complications during drilling. Additionally, employing proper techniques during use can significantly impact drill bit longevity. This includes using appropriate speeds and pressures as previously discussed, as well as ensuring adequate cooling throughout the process.

After each use, cleaning drill bits thoroughly removes any debris or residue that could contribute to dulling over time. By implementing these maintenance practices, one can ensure that drill bits remain sharp and effective for longer periods, ultimately enhancing overall productivity.

Achieving Consistent and Uniform Hole Depths in Egyptian Granite

Achieving consistent and uniform hole depths in Egyptian granite is essential for many applications, particularly in construction or decorative projects where precision is key. One effective method for ensuring uniformity is to use depth stops on drill bits or adjustable collars that limit how far the bit can penetrate into the stone. These devices provide a physical barrier that helps maintain consistent depths across multiple holes.

Another technique involves regularly checking hole depth during drilling using measuring tools such as calipers or depth gauges. This practice allows for immediate adjustments if discrepancies are detected, ensuring that all holes meet specified depth requirements. By employing these strategies, one can achieve greater consistency in hole depths when working with Egyptian granite, leading to more professional results.

Finishing and Polishing Techniques for Drilled Holes in Egyptian Granite

Once drilling is complete, finishing and polishing techniques play a vital role in enhancing the appearance of drilled holes in Egyptian granite. The rough edges left behind after drilling can detract from the overall aesthetic appeal of the stone; therefore, smoothing these edges is essential for achieving a polished look. One common method involves using diamond polishing pads or grinding wheels specifically designed for stone surfaces.

These tools allow for gradual smoothing of edges while also providing a polished finish that highlights the natural beauty of the granite. It is important to start with coarser grits before progressing to finer ones to achieve optimal results. Additionally, applying a sealant after polishing can help protect the surface from stains or damage while enhancing its shine.

By mastering these finishing techniques, one can elevate the overall quality of drilled holes in Egyptian granite.

Safety Precautions and Best Practices for Precision Drilling in Egyptian Granite

Safety should always be a top priority when engaging in precision drilling activities involving Egyptian granite. The inherent risks associated with power tools necessitate adherence to strict safety protocols to prevent accidents or injuries.

Additionally, ensuring that all tools are properly maintained and functioning correctly before use is crucial for minimizing risks during operation. Regular inspections of equipment can help identify potential issues before they escalate into serious problems. Furthermore, maintaining clear communication among team members during collaborative projects fosters a safer work environment by ensuring everyone is aware of their surroundings and potential hazards.

By prioritizing safety precautions and best practices, individuals can engage in precision drilling with greater confidence while minimizing risks associated with working with Egyptian granite.

In the realm of Egyptian granite precision drilling techniques, understanding the historical context and advancements in technology is crucial. For a deeper insight into the methodologies and innovations that have shaped this field, you can explore the article available at Real Lore and Order. This resource provides valuable information that complements the study of drilling techniques used in ancient and modern applications.

WATCH THIS! The Impossible Technology They Erased From History

FAQs

What is precision drilling in the context of Egyptian granite?

Precision drilling refers to the highly accurate and controlled process of creating holes or cavities in Egyptian granite, ensuring minimal damage and exact dimensions for construction or decorative purposes.

Why is precision drilling important for Egyptian granite?

Precision drilling is crucial because Egyptian granite is a dense and hard natural stone. Accurate drilling prevents cracking, chipping, and wastage, maintaining the stone’s structural integrity and aesthetic appeal.

What tools are commonly used for precision drilling in Egyptian granite?

Diamond-tipped drill bits and core drills are commonly used due to their hardness and ability to cut through tough granite efficiently while maintaining precision.

How does water cooling assist in precision drilling of Egyptian granite?

Water cooling helps reduce heat generated during drilling, which prevents damage to the granite and extends the life of the drill bits. It also helps remove dust and debris from the drilling area.

Are there specific techniques to ensure accuracy in drilling Egyptian granite?

Yes, techniques include using CNC (Computer Numerical Control) machines for automated precision, employing pilot holes to guide larger drills, and maintaining steady pressure and speed during drilling.

Can precision drilling be done on-site or only in factories?

Precision drilling can be performed both on-site and in factories, depending on the project requirements. Portable drilling equipment allows for on-site work, while factory settings may use more advanced machinery.

What are common applications of precision drilling in Egyptian granite?

Applications include creating holes for fixtures, anchors, plumbing, electrical conduits, decorative inlays, and custom architectural elements.

How does the quality of Egyptian granite affect drilling techniques?

Higher quality granite with fewer natural flaws allows for smoother drilling and better precision. Variations in grain and hardness may require adjustments in drilling speed and tool selection.

Is specialized training required for precision drilling in Egyptian granite?

Yes, operators typically require training to handle the equipment properly, understand the stone’s properties, and apply the correct techniques to avoid damage and ensure precision.

What safety measures are recommended during precision drilling of Egyptian granite?

Safety measures include wearing protective eyewear, gloves, and masks to guard against dust and debris, ensuring proper ventilation, and using equipment with safety features to prevent accidents.