The landscape of American industry, once a robust testament to its economic might, has undergone significant transformations over the past several decades. While the narrative often focuses on the outsourcing of manufacturing and the decline of traditional industrial hubs, a less prominent yet equally crucial phenomenon is now gaining traction: industrial relocation within the United States. This internal movement, driven by a complex interplay of economic, social, and geopolitical factors, is a significant force in the ongoing re-shaping of the nation’s economic geography. Understanding this internal migration of industries is paramount for policymakers, businesses, and citizens alike, as it dictates employment opportunities, regional development, and the overall competitiveness of the American economy.

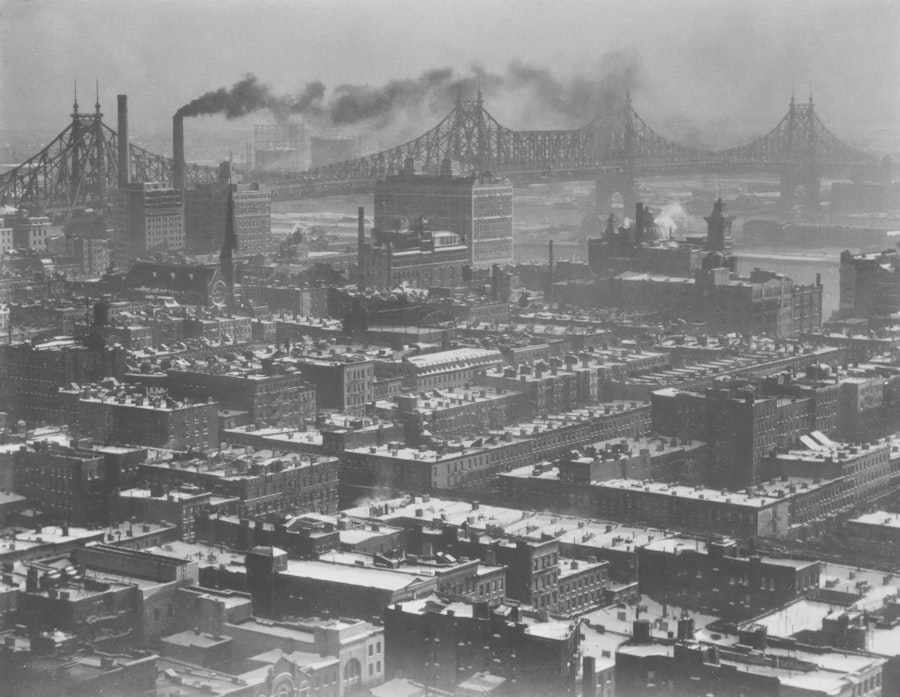

The historical trajectory of American industry is marked by distinct phases of geographic concentration. The early 20th century saw the ascendancy of the “Rust Belt,” where heavy industry clustered around abundant natural resources and transportation networks. However, globalization and technological advancements initiated a period of deindustrialization in these regions, leading to economic hardship and population decline. Today, a new chapter is being written, where the pursuit of efficiency, resilience, and strategic advantage is inspiring a domestic re-evaluation of industrial strongholds. The recent report highlights the impact of [Germany factory closures] on the European economy.

Erosion of Traditional Industrial Bases

The decline of manufacturing in the Northeast and Midwest was a multifaceted phenomenon. Factors included:

- Global Competition: Lower labor costs and less stringent regulations in other countries made overseas production more attractive for many industries.

- Technological Advancements: Automation and robotics reduced the demand for manual labor in manufacturing, fundamentally altering the workforce requirements.

- Shifting Consumer Demands: A move away from heavy industrial products towards consumer goods and services further impacted traditional manufacturing sectors.

Emergence of New Industrial Corridors

As older industrial centers faced challenges, new regions began to attract investment and foster innovation. These emerging corridors often possessed:

- Lower Operating Costs: States with more favorable tax structures, lower land costs, and a less unionized workforce became attractive alternatives.

- Proximity to New Markets: The growth of population centers in the South and West created new domestic markets for goods and services.

- Access to Skilled Labor: Investments in technical education and workforce development in some areas cultivated a skilled labor pool tailored to modern industrial needs.

Industrial relocation in the United States has become a significant topic of discussion, especially in light of recent economic shifts and supply chain challenges. For those interested in exploring this subject further, a related article can be found at Real Lore and Order, which delves into the factors driving companies to move their operations and the implications for local economies.

Drivers of Domestic Relocation

The decision for a company to relocate its operations is a strategic calculus involving numerous variables. While the allure of international markets once held sway, a renewed focus on domestic strengths is now guiding many businesses. These drivers can be categorized into economic, geopolitical, and logistical considerations.

Economic Incentives and Regulatory Environments

One of the most significant pulls for industrial relocation domestically is the promise of a more favorable economic climate. States and localities actively compete to attract new businesses, offering a range of incentives that can significantly impact a company’s bottom line.

- Tax Abatements: Reductions or exemptions from property, sales, or income taxes can make a new location financially appealing for an extended period.

- Grants and Subsidies: Direct financial assistance for job creation, infrastructure development, or training programs can offset initial relocation costs.

- Favorable Regulatory Regimes: States with streamlined permitting processes and less burdensome environmental regulations can offer a quicker path to operation.

- Lower Labor Costs: While varying across industries and regions, some areas offer a more competitive wage environment compared to established industrial hubs.

Supply Chain Resilience and Nearshoring

The COVID-19 pandemic exposed the fragility of global supply chains, acting as a powerful catalyst for re-evaluating sourcing strategies. This vulnerability has accelerated the trend of “nearshoring,” where companies bring production closer to their end markets.

- Reduced Lead Times: Domestic production significantly shortens the time required for goods to travel from factory to consumer, enhancing responsiveness to market fluctuations.

- Mitigation of Geopolitical Risks: Relying on domestic suppliers reduces exposure to international trade disputes, political instability, and tariffs.

- Improved Quality Control: Closer proximity allows for more direct oversight of manufacturing processes, potentially leading to higher quality products.

- Enhanced Inventory Management: Shorter supply chains allow for leaner inventory practices, reducing storage costs and waste.

Workforce Availability and Development

The availability of a skilled workforce is a critical component of any successful industrial operation. Regions that proactively invest in workforce development and education are well-positioned to attract and retain businesses.

- Technical and Vocational Training: Community colleges and technical schools play a vital role in providing specialized training relevant to modern manufacturing.

- University Partnerships: Collaborations between industry and academia can foster research and development, and also produce graduates with in-demand skills.

- Apprenticeship Programs: These programs offer hands-on training and a direct pipeline from education to employment, addressing skills gaps in critical sectors.

- Quality of Life Factors: The availability of affordable housing, good schools, and recreational opportunities also plays a role in attracting and retaining employees.

Case Studies and Regional Shifts

The phenomenon of industrial relocation is not speculative; it is actively shaping the economic landscape of various regions. Observing these shifts provides tangible evidence of the drivers at play and their concrete outcomes.

The Rise of the “Battery Belt”

A prime example of a nascent industrial corridor is the emerging “Battery Belt,” primarily located in the Southeastern United States. This region is witnessing significant investment in electric vehicle (EV) manufacturing and battery production.

- Strategic Location: Proximity to key automotive manufacturers and logistical advantages for distribution.

- State Incentives: Aggressive incentive packages offered by states like Georgia, Tennessee, and Kentucky have attracted major players.

- Workforce Preparedness: Investments in specialized training programs are creating a labor pool for these technologically advanced manufacturing processes.

The Resurgence of Semiconductor Manufacturing

The vulnerabilities in the global semiconductor supply chain, highlighted during the pandemic, have spurred a national effort to bring chip manufacturing back to American soil.

- CHIPS and Science Act: This federal legislation provides substantial financial incentives for semiconductor research, development, and manufacturing.

- Arizona’s Silicon Desert: Arizona has become a focal point for new semiconductor fabrication plants, leveraging its existing tech infrastructure and qualified workforce.

- Ohio’s Tech Hub Ambitions: Significant investments are also being made in Ohio, aiming to establish another major semiconductor manufacturing hub.

Challenges and Considerations

While the benefits of domestic industrial relocation are substantial, the process is not without its challenges. Policymakers and businesses must navigate a complex array of factors to ensure successful transitions and sustainable growth.

Infrastructure Development

New industrial sites often require significant investments in supporting infrastructure. Without adequate roads, utilities, and broadband connectivity, even the most attractive incentive packages may fall short.

- Transportation Networks: Upgrading and expanding highways, rail lines, and port facilities are crucial for efficient logistics.

- Energy Grids: Modern industrial facilities, especially those in energy-intensive sectors like semiconductor manufacturing, require robust and reliable power grids.

- Water Management: Access to sufficient water resources is a growing concern in many regions, necessitating careful planning for industrial development.

Environmental Impact and Sustainability

The relocation of industrial facilities must be undertaken with a strong commitment to environmental stewardship. The pursuit of economic growth should not come at the expense of ecological integrity.

- Sustainable Manufacturing Practices: Encouraging the adoption of greener technologies and processes minimizes environmental footprints.

- Waste Management: Implementing robust systems for waste reduction, recycling, and responsible disposal is essential.

- Resource Conservation: Strategies for efficient water and energy use are increasingly important as resources become scarcer.

Social and Economic Equity

The benefits of industrial relocation must be distributed equitably across communities. Ensuring that new jobs are accessible to all segments of the population and that local residents benefit from economic growth is paramount.

- Affordable Housing: Influxes of new workers can strain local housing markets, necessitating proactive planning for affordable housing options.

- Community Engagement: Involving local communities in the planning process helps to address concerns and ensure that development aligns with local values.

- Workforce Diversity and Inclusion: Efforts to recruit and train a diverse workforce contribute to social equity and economic resilience.

Industrial relocation within the United States has become a significant topic as companies seek to optimize their operations and reduce costs. A recent article discusses the various factors influencing this trend, including labor availability and supply chain logistics. For further insights on this subject, you can read more in the article found here. Understanding these dynamics is crucial for businesses considering a move, as they navigate the complexities of a changing economic landscape.

The Path Forward: A National Imperative

| Metric | Value | Year | Notes |

|---|---|---|---|

| Number of Industrial Relocations | 1,200 | 2023 | Estimated relocations within the US |

| Top States for Industrial Relocation | Texas, Georgia, North Carolina | 2023 | States with highest inbound industrial moves |

| Average Distance of Relocation | 350 miles | 2023 | Average distance companies moved their operations |

| Primary Reasons for Relocation | Lower operating costs, tax incentives, labor availability | 2023 | Top factors influencing relocation decisions |

| Percentage of Relocations to Southern States | 45% | 2023 | Share of relocations moving to southern US states |

| Impact on Employment | +15,000 jobs created | 2023 | Net jobs gained in relocation destination areas |

| Average Time to Complete Relocation | 9 months | 2023 | Typical duration from decision to operational status |

The revitalization of American industry through domestic relocation is not merely an economic trend; it is a national imperative driven by a desire for greater resilience, security, and prosperity. It represents a strategic pivot, recognizing that a robust domestic industrial base is a cornerstone of national strength.

Strategic Planning and Collaboration

Effective industrial relocation requires a concerted effort from all levels of government, industry, and educational institutions.

- National Industrial Strategy: A cohesive federal strategy can provide overarching guidance and coordination for state-level initiatives.

- Public-Private Partnerships: Collaborative ventures between government and businesses can leverage expertise and resources for large-scale projects.

- Regional Economic Development Organizations: These organizations play a crucial role in coordinating efforts and attracting investment at the local level.

Investment in Innovation and Research

Keeping pace with global technological advancements requires sustained investment in research and development. This fosters a competitive edge and secures America’s position as an industrial leader.

- Advanced Manufacturing Technologies: Supporting the development and adoption of technologies like additive manufacturing, AI, and robotics is essential.

- Green Industrial Initiatives: Investing in clean energy technologies and sustainable manufacturing processes positions the U.S. at the forefront of the green economy.

- Talent Development for Future Industries: Foresight in identifying future industrial needs and training the next generation of skilled workers is crucial.

In conclusion, the movement of industries within the United States is a significant and evolving narrative. It is a testament to the nation’s adaptability and its enduring pursuit of economic strength. As this internal migration continues, it will undoubtedly reshape the economic tapestry of America, creating new hubs of innovation and opportunity. For citizens, understanding these forces is akin to reading the compass of their nation’s future, influencing where jobs will be, what skills will be valued, and how communities will transform. For businesses, it is about finding the fertile ground where their seeds of ambition can take root and flourish. The journey of revitalizing America through industrial relocation is complex, but it is a journey toward a more resilient, competitive, and domestically anchored economic future.

WATCH THIS 🔴 SHOCKING: Why Germany’s Factory Exodus Is Permanent (Not Temporary)

FAQs

What is industrial relocation in the United States?

Industrial relocation in the United States refers to the process of moving manufacturing facilities, factories, or industrial operations from one location to another within the country. This can involve shifting to a different state, city, or region to optimize costs, access new markets, or improve operational efficiency.

Why do companies choose to relocate their industrial operations within the U.S.?

Companies may relocate their industrial operations for various reasons, including reducing labor and operational costs, accessing better infrastructure, proximity to suppliers or customers, favorable tax incentives, regulatory advantages, or to modernize facilities.

What are some common challenges faced during industrial relocation in the U.S.?

Challenges can include logistical complexities, downtime during the move, regulatory compliance, workforce retention or recruitment in the new location, environmental considerations, and the costs associated with moving equipment and setting up new facilities.

Are there any government incentives for industrial relocation in the United States?

Yes, many states and local governments offer incentives such as tax breaks, grants, and subsidies to attract industrial businesses. These incentives aim to promote economic development, job creation, and investment in their regions.

How does industrial relocation impact local economies in the United States?

Industrial relocation can significantly impact local economies by creating jobs, increasing tax revenues, and stimulating related businesses. Conversely, the departure of industrial operations can lead to job losses and economic decline in the affected areas.