The history of ancient metalworking is a fascinating journey that traces the evolution of human ingenuity and craftsmanship. It began in the Neolithic period, around 6000 BCE, when early humans first discovered that certain ores could be heated to produce malleable metals. This marked a significant turning point in human civilization, as metalworking allowed for the creation of tools and weapons that were far superior to their stone counterparts.

The transition from the Stone Age to the Bronze Age around 3000 BCE heralded a new era, where copper and tin were combined to create bronze, a material that revolutionized agriculture, warfare, and art. As societies advanced, so did their metalworking techniques.

Meanwhile, the Mesopotamians developed sophisticated methods for smelting and alloying metals, which laid the groundwork for future advancements. The spread of metalworking techniques across different regions facilitated trade and cultural exchange, leading to a rich tapestry of innovations that would shape the course of history.

Key Takeaways

- Ancient metalworking dates back to at least 6000 BCE, with evidence of copper smelting in the Middle East.

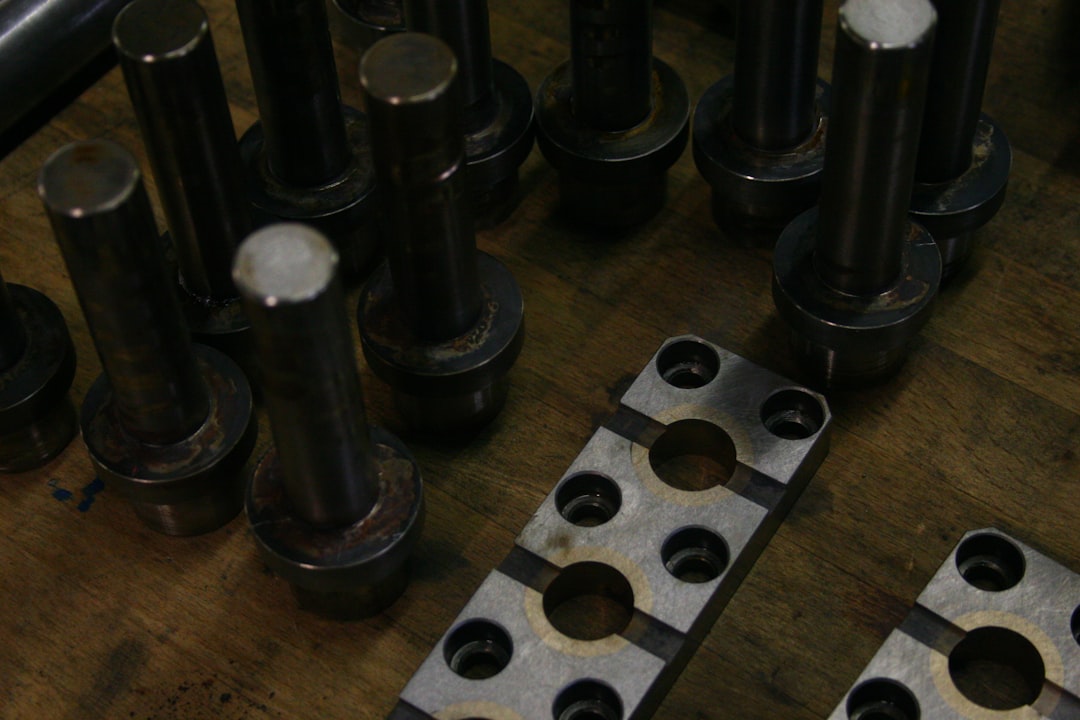

- Tools and materials used in ancient metalworking included hammers, anvils, tongs, and crucibles, along with metals such as copper, bronze, iron, and gold.

- Techniques for smelting and refining metals involved heating ores in furnaces to extract the metal, and then further refining it through processes like cupellation and cementation.

- The art of casting and molding metal allowed for the creation of intricate and detailed objects, such as jewelry, statues, and weapons.

- Ancient metalworking varied greatly across different cultures and civilizations, with each developing unique methods and styles.

Tools and Materials Used in Ancient Metalworking

Ancient metalworkers relied on a variety of tools and materials to create their masterpieces. The primary materials included copper, bronze, gold, silver, and iron, each chosen for its unique properties and suitability for specific applications. Copper was one of the first metals to be used due to its availability and malleability, while bronze became favored for its strength and durability.

Gold and silver were often reserved for decorative purposes, reflecting wealth and status in ancient societies. The tools employed by ancient metalworkers were rudimentary yet effective. Hammers made from stone or harder metals were used to shape and flatten pieces of metal, while anvils provided a sturdy surface for forging.

Tongs made from wood or metal helped manipulate hot materials safely. As techniques evolved, so did the complexity of tools; bellows were introduced to increase the temperature of furnaces, allowing for more efficient smelting processes. These tools not only facilitated the creation of functional items but also enabled artisans to express their creativity through intricate designs.

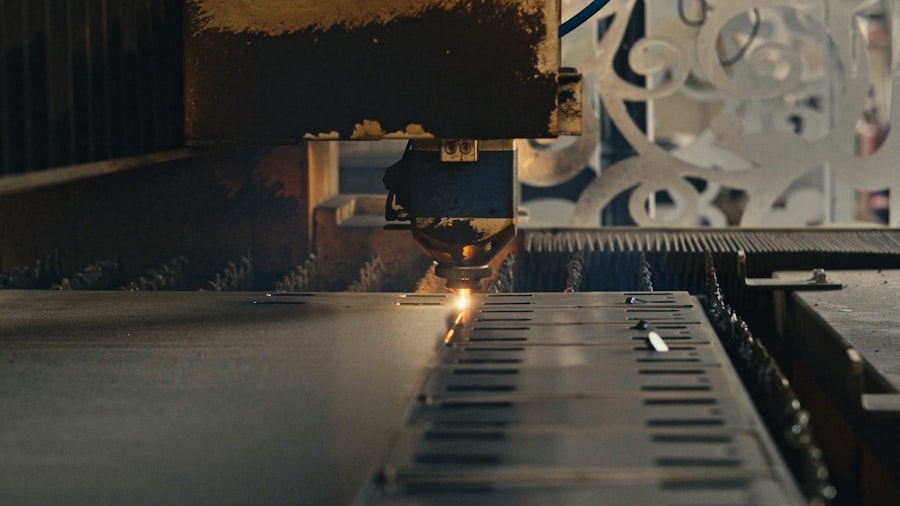

Techniques for Smelting and Refining Metals

The techniques for smelting and refining metals in ancient times were both innovative and labor-intensive. Smelting involved heating ores in a furnace to extract the metal from its mineral form. This process required a deep understanding of materials and temperatures, as different metals had varying melting points.

Ancient metalworkers often used charcoal as fuel, which provided the necessary heat while also contributing carbon to the metal, enhancing its properties. Refining was another critical step in metalworking, aimed at removing impurities from the extracted metal. This was achieved through processes such as cupellation, where lead was used to absorb impurities from silver or gold ores.

The knowledge of these techniques was often passed down through generations, with artisans honing their skills over time. The ability to produce high-quality metals not only improved tool-making but also elevated the status of metalworkers within their communities.

The Art of Casting and Molding Metal

| Technique | Advantages | Disadvantages |

|---|---|---|

| Sand Casting | Low cost, versatile, suitable for large parts | Low dimensional accuracy, rough surface finish |

| Investment Casting | High dimensional accuracy, intricate shapes | Higher cost, limited to smaller parts |

| Die Casting | High production rate, good surface finish | High initial cost, limited to certain alloys |

| Centrifugal Casting | Uniform grain structure, good for cylindrical parts | Limited to cylindrical shapes, higher cost |

Casting and molding were pivotal techniques in ancient metalworking that allowed artisans to create complex shapes and designs. The process typically involved pouring molten metal into a pre-formed mold made from clay or stone. Once cooled, the mold was removed to reveal the finished product.

This technique enabled the mass production of items such as tools, weapons, and decorative objects, significantly impacting various aspects of daily life. The artistry involved in casting was not merely functional; it also reflected cultural values and beliefs. Many ancient civilizations adorned their cast metal objects with intricate designs that told stories or represented deities.

For instance, the lost-wax casting method allowed for greater detail in sculptures and jewelry, showcasing the skill of the artisan. This blend of utility and artistry exemplified the importance of metalworking in ancient societies, where objects were often imbued with symbolic meaning.

Ancient Metalworking in Different Cultures and Civilizations

Metalworking practices varied significantly across different cultures and civilizations, each contributing unique techniques and styles to the craft. In ancient Egypt, goldsmiths created exquisite jewelry adorned with precious stones, reflecting the civilization’s wealth and religious beliefs. The use of gold was not only practical but also symbolic, as it was associated with immortality and divine power.

In contrast, the Chinese civilization made remarkable advancements in ironworking during the Zhou Dynasty (1046–256 BCE). They developed cast iron techniques that allowed for stronger tools and weapons, which played a crucial role in agricultural expansion and military prowess. Similarly, the Celts in Europe were known for their intricate metalwork, particularly in creating decorative items such as brooches and weaponry that showcased their artistic flair.

Advancements in Ancient Metalworking Technology

The advancements in ancient metalworking technology were driven by necessity and innovation. As societies grew more complex, so did their demands for stronger tools and weapons. The introduction of alloying techniques allowed metalworkers to combine different metals to enhance their properties.

For example, the addition of tin to copper created bronze, which was significantly harder than pure copper. Another significant advancement was the development of more efficient furnaces and bellows systems that enabled higher temperatures during smelting processes. This not only improved the quality of metals produced but also expanded the range of materials that could be worked with.

The ability to produce iron on a larger scale during the Iron Age marked a turning point in technology, leading to stronger agricultural implements and weaponry that would dominate warfare for centuries.

The Role of Metalworking in Ancient Trade and Commerce

Metalworking played a crucial role in ancient trade and commerce, serving as both a catalyst for economic growth and a means of cultural exchange. The production of high-quality metal goods created demand not only within local communities but also across vast distances. Artisans often traded their products for raw materials or other goods, fostering relationships between different cultures.

For instance, the Silk Road connected East and West, allowing for the transfer of knowledge about metallurgy between civilizations such as China and Rome. This exchange enriched both cultures, leading to advancements in technology and artistry that would have lasting impacts on future generations.

Preservation and Restoration of Ancient Metal Artifacts

The preservation and restoration of ancient metal artifacts are vital for understanding historical contexts and technological advancements in metalworking. Many artifacts have survived through centuries due to favorable environmental conditions or careful burial practices. However, exposure to air and moisture can lead to corrosion and deterioration over time.

Conservation efforts often involve meticulous cleaning processes to remove corrosion while preserving as much original material as possible. Techniques such as electrolysis can be employed to reverse some damage caused by corrosion. Additionally, researchers study these artifacts to gain insights into ancient manufacturing techniques, trade practices, and cultural significance.

By preserving these treasures, modern society can maintain a tangible connection to its past.

The Legacy of Ancient Metalworking Techniques in Modern Industry

The legacy of ancient metalworking techniques continues to influence modern industry in profound ways. Many contemporary manufacturing processes can trace their roots back to ancient practices. For instance, casting techniques developed thousands of years ago are still employed today in various industries, from automotive to aerospace.

Moreover, the principles of metallurgy established by ancient artisans laid the groundwork for modern materials science. Understanding how different metals interact with one another has led to innovations in alloy production that enhance performance across numerous applications. The artistry inherent in ancient metalwork also inspires contemporary designers who seek to blend functionality with aesthetic appeal.

Exploring Ancient Metalworking Sites and Artifacts

Exploring ancient metalworking sites offers invaluable insights into past civilizations and their technological prowess. Archaeological excavations have uncovered workshops where artisans crafted tools and jewelry, revealing not only their methods but also their social structures and economic systems. Sites such as those found in Mesopotamia or Egypt provide a glimpse into how communities organized themselves around metal production.

Artifacts recovered from these sites serve as tangible links to history. Museums around the world showcase these treasures, allowing visitors to appreciate the skill and artistry involved in ancient metalworking. Each piece tells a story—of trade routes traveled, cultural exchanges made, and technological advancements achieved—highlighting the significance of metalworking throughout human history.

Learning and Reviving Ancient Metalworking Techniques

In recent years, there has been a resurgence of interest in learning and reviving ancient metalworking techniques among artisans and craftsmen worldwide. Workshops dedicated to traditional methods are becoming increasingly popular as individuals seek to reconnect with historical practices that have been overshadowed by modern technology. This revival not only preserves valuable skills but also fosters a deeper appreciation for craftsmanship.

Many contemporary artisans draw inspiration from ancient techniques while incorporating modern materials and technologies into their work. This fusion allows for innovative creations that honor traditional methods while pushing boundaries in design and functionality. By embracing these ancient practices, today’s craftsmen contribute to a living legacy that celebrates human creativity across generations.

In conclusion, ancient metalworking is a rich field that encompasses history, culture, technology, and artistry. From its humble beginnings with simple tools to complex casting methods that shaped civilizations, metalworking has left an indelible mark on human progress. As modern society continues to explore these ancient techniques through preservation efforts and contemporary craftsmanship, it ensures that the legacy of those early artisans endures for future generations to appreciate and learn from.

In recent years, the field of archaeology has been buzzing with excitement over the discovery of ancient metalworking secrets that have shed light on the technological prowess of early civilizations. These findings have not only deepened our understanding of historical craftsmanship but have also sparked interest in related studies. For instance, an article on Real Lore and Order delves into the intricate techniques used by ancient blacksmiths, exploring how these methods have influenced modern metalworking practices. This piece provides a fascinating glimpse into the past, revealing the sophisticated skills and knowledge that were once thought lost to time.

WATCH THIS! 👀 History Is Hiding 50 Impossible Inventions

FAQs

What are some ancient metalworking techniques that have been revealed?

Some ancient metalworking techniques that have been revealed include the use of alloys such as bronze and iron, as well as the use of casting, forging, and welding methods.

How have these ancient metalworking techniques been revealed?

These ancient metalworking techniques have been revealed through archaeological discoveries, experimental archaeology, and the study of ancient artifacts and written records.

What insights have been gained from the study of ancient metalworking techniques?

The study of ancient metalworking techniques has provided insights into the technological advancements and skills of ancient civilizations, as well as their trade networks, cultural practices, and artistic achievements.

Why is the study of ancient metalworking techniques important?

The study of ancient metalworking techniques is important because it helps us understand the development of human civilization, technological innovation, and the cultural and economic significance of metalworking in ancient societies.

What are some examples of ancient metalworking secrets that have been revealed?

Some examples of ancient metalworking secrets that have been revealed include the use of sophisticated casting techniques to create intricate metal objects, the development of high-quality steel in ancient times, and the use of metal alloys for specific purposes such as weapons and jewelry.