Wootz steel, a legendary material known for its remarkable properties, has captivated metallurgists and historians alike for centuries. Originating from ancient India, this high-carbon steel is often celebrated for its unique combination of strength, durability, and aesthetic appeal. The allure of Wootz steel lies not only in its physical characteristics but also in the rich cultural heritage it embodies.

As a precursor to modern high-performance steels, Wootz steel represents a significant chapter in the history of metallurgy, showcasing the advanced techniques employed by ancient artisans. The production of Wootz steel dates back to around 300-500 AD, with its roots deeply embedded in the Indian subcontinent. The craftsmanship involved in creating this steel was a closely guarded secret, passed down through generations.

The intricate patterns that emerged during its production have led to its association with the famed Damascus steel, further enhancing its mystique. As researchers delve deeper into the properties and manufacturing processes of Wootz steel, they uncover not only the technical aspects but also the cultural narratives that shaped its legacy.

Key Takeaways

- Wootz steel is a type of crucible steel that originated in South India and was highly prized for its exceptional strength and sharpness.

- Wootz steel has a rich historical significance, as it was used to make legendary swords such as the Damascus steel, which were renowned for their superior quality and cutting ability.

- The composition of Wootz steel includes a unique combination of iron, carbon, and trace elements such as vanadium, chromium, and tungsten, which contribute to its distinctive properties.

- The manufacturing process of Wootz steel involves a complex and sophisticated technique of crucible steelmaking, which includes multiple stages of melting, solidification, and forging.

- The unique microstructure of Wootz steel, characterized by its intricate banding patterns and carbide clusters, contributes to its exceptional mechanical properties and sharpness.

Historical Significance of Wootz Steel

The historical significance of Wootz steel cannot be overstated. It played a pivotal role in the development of weaponry and tools in ancient civilizations, particularly in India and the Middle East. The exceptional qualities of Wootz steel made it highly sought after for crafting swords and blades that were not only functional but also aesthetically pleasing.

The reputation of Wootz steel spread far beyond its place of origin, influencing trade routes and cultural exchanges between different regions.

Notable figures such as Marco Polo documented their encounters with this remarkable material, describing the swords made from Wootz steel as “the finest in the world.” This historical narrative highlights the significance of Wootz steel not just as a material but as a symbol of technological advancement and cultural exchange during a time when metallurgy was a key driver of civilization.

The Composition of Wootz Steel

The composition of Wootz steel is one of the factors that contribute to its unique properties. Typically, it contains a high carbon content, often ranging between 1.5% to 2.0%, which imparts strength and hardness to the material. Additionally, trace elements such as manganese, silicon, and phosphorus can be found in varying amounts, influencing the overall characteristics of the steel.

This specific composition allows Wootz steel to achieve a balance between hardness and ductility, making it suitable for various applications. Moreover, the presence of carbon in Wootz steel is crucial for its microstructural development. The carbon content facilitates the formation of cementite (iron carbide) within the steel matrix, which contributes to its distinctive patterns and enhances its mechanical properties.

Understanding the precise composition of Wootz steel is essential for modern researchers aiming to replicate its qualities or explore its potential applications in contemporary metallurgy.

The Manufacturing Process of Wootz Steel

| Stage | Description |

|---|---|

| Mining | Iron ore is extracted from the ground and transported to the steel mill. |

| Smelting | The iron ore is melted in a blast furnace and impurities are removed to produce pig iron. |

| Conversion to Steel | Pig iron is converted to steel through the Bessemer process or the open hearth process. |

| Wootz Steel Formation | Wootz steel is produced by a crucible process involving the addition of specific ingredients like wood, leaves, and other organic materials to the steel. |

| Forging | The steel is forged into desired shapes and sizes using hammers and presses. |

| Heat Treatment | The steel is heated and cooled in a controlled manner to achieve the desired properties like hardness and toughness. |

The manufacturing process of Wootz steel is an intricate art that combines traditional techniques with a deep understanding of materials science. The process begins with the selection of iron ore, which is then subjected to a series of heating and cooling cycles in a crucible. This method allows for the controlled introduction of carbon into the iron, resulting in a high-carbon steel that possesses unique properties.

One of the defining features of Wootz steel production is the use of crucible furnaces, which enable artisans to achieve precise temperature control during the smelting process. The crucibles are often lined with clay and filled with iron ore and carbon-rich materials such as charcoal. As the mixture is heated, carbon diffuses into the iron, leading to the formation of a homogeneous alloy.

This meticulous process requires not only technical skill but also an intuitive understanding of materials, making it a true testament to ancient metallurgical expertise.

The Unique Microstructure of Wootz Steel

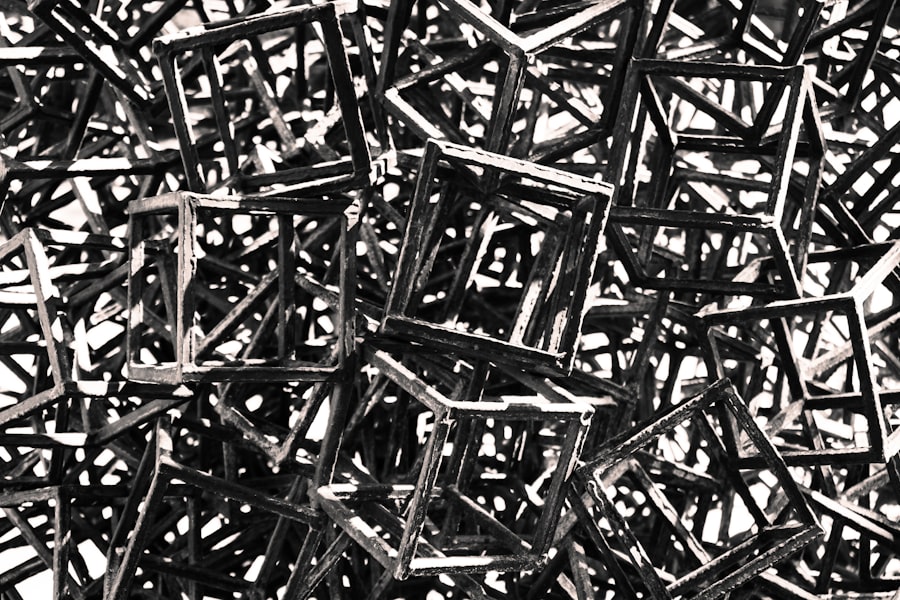

The microstructure of Wootz steel is what sets it apart from other types of steel. Characterized by distinctive banding patterns and a fine distribution of cementite within a ferrite matrix, this microstructure contributes to both the aesthetic appeal and mechanical performance of the material. The unique patterns observed in Wootz steel are often likened to flowing water or intricate floral designs, making each piece not only functional but also a work of art.

This microstructural arrangement is a result of the specific cooling rates and heat treatments employed during production. As Wootz steel cools, the carbon-rich regions form cementite particles that are interspersed within the iron matrix. This distribution enhances the hardness and wear resistance of the steel while maintaining sufficient ductility for practical use.

Understanding this microstructure is crucial for modern scientists seeking to unlock the secrets behind Wootz steel’s legendary performance.

Tools and Techniques for Unveiling the Wootz Steel Microstructure

To unveil the microstructure of Wootz steel, researchers employ a variety of advanced tools and techniques that allow for detailed analysis at microscopic levels. Optical microscopy serves as an initial step in examining the surface features and patterns present in Wootz steel samples. By using polarized light microscopy, researchers can enhance contrast and reveal intricate details that characterize this unique material.

In addition to optical microscopy, scanning electron microscopy (SEM) has become an invaluable tool for studying the microstructure of Wootz steel. SEM provides high-resolution images that allow researchers to observe surface morphology and elemental composition with great precision. This technique enables scientists to analyze grain boundaries, phase distributions, and other critical features that contribute to the overall performance of Wootz steel.

Scanning Electron Microscopy (SEM) Analysis of Wootz Steel

Scanning electron microscopy (SEM) analysis has revolutionized the study of materials like Wootz steel by providing detailed insights into their microstructural characteristics. SEM operates by scanning a focused beam of electrons across a sample’s surface, generating high-resolution images that reveal topographical features at nanometer scales. For Wootz steel, SEM analysis allows researchers to visualize the unique banding patterns and cementite distribution that define its microstructure.

Through SEM analysis, researchers can also perform energy-dispersive X-ray spectroscopy (EDS) to determine the elemental composition of specific regions within Wootz steel samples. This capability is particularly important for understanding how variations in composition influence mechanical properties and performance. By correlating microstructural features observed through SEM with compositional data obtained from EDS, scientists can gain deeper insights into the relationship between structure and performance in Wootz steel.

Transmission Electron Microscopy (TEM) Analysis of Wootz Steel

Transmission electron microscopy (TEM) offers an even more refined approach to studying the microstructure of Wootz steel at atomic resolutions. Unlike SEM, which examines surface features, TEM allows researchers to investigate internal structures by transmitting electrons through ultra-thin samples. This technique provides invaluable information about crystal structures, dislocation densities, and phase transformations within Wootz steel.

TEM analysis has revealed critical insights into the nanoscale features that contribute to the exceptional properties of Wootz steel. For instance, researchers can observe how cementite particles are distributed within the ferrite matrix at atomic levels, shedding light on how these arrangements affect hardness and toughness. By combining TEM findings with other analytical techniques, scientists can develop comprehensive models that explain how microstructural characteristics translate into macroscopic performance.

X-ray Diffraction (XRD) Analysis of Wootz Steel

X-ray diffraction (XRD) analysis serves as another powerful tool for characterizing the crystalline structure of Wootz steel. By directing X-rays at a sample and measuring the resulting diffraction patterns, researchers can identify phase compositions and crystallographic orientations within the material. This technique is particularly useful for determining how different phases contribute to the overall properties of Wootz steel.

XRD analysis has revealed that Wootz steel typically exhibits a complex mixture of phases, including ferrite and cementite, which play crucial roles in defining its mechanical behavior. By analyzing peak positions and intensities in XRD patterns, researchers can quantify phase fractions and assess how variations in processing conditions influence phase stability. This information is vital for understanding how historical manufacturing techniques may have impacted the performance characteristics observed in ancient artifacts made from Wootz steel.

Insights Gained from Unveiling the Wootz Steel Microstructure

The exploration of Wootz steel’s microstructure has yielded profound insights into its exceptional properties and historical significance. By employing advanced analytical techniques such as SEM, TEM, and XRD, researchers have been able to unravel the complex relationships between composition, processing conditions, and resulting microstructural features. These insights not only enhance our understanding of ancient metallurgical practices but also inform modern materials science.

One key finding is that the unique banding patterns observed in Wootz steel are not merely aesthetic; they are indicative of specific cooling rates and carbon distributions during production. This knowledge allows modern metallurgists to replicate similar patterns in contemporary high-performance steels, potentially leading to advancements in tool manufacturing and other applications where strength and durability are paramount.

Applications of Understanding the Wootz Steel Microstructure

The knowledge gained from studying the microstructure of Wootz steel has far-reaching implications for various fields beyond historical metallurgy. In contemporary materials science, insights into how microstructural features influence mechanical properties can guide the development of new alloys with tailored characteristics for specific applications.

Furthermore, understanding the principles behind Wootz steel’s production methods may inspire innovative approaches to modern manufacturing processes. By integrating traditional techniques with cutting-edge technology, researchers can explore new avenues for creating high-performance materials that meet contemporary demands while honoring ancient craftsmanship. Ultimately, the legacy of Wootz steel continues to inspire advancements in metallurgy and materials science today.

Wootz steel, renowned for its exceptional properties and historical significance, has been the subject of extensive microstructure analysis to understand its unique characteristics. A related article that delves into the intricacies of this analysis can be found at